Preserve Uptime, Reduce Emissions

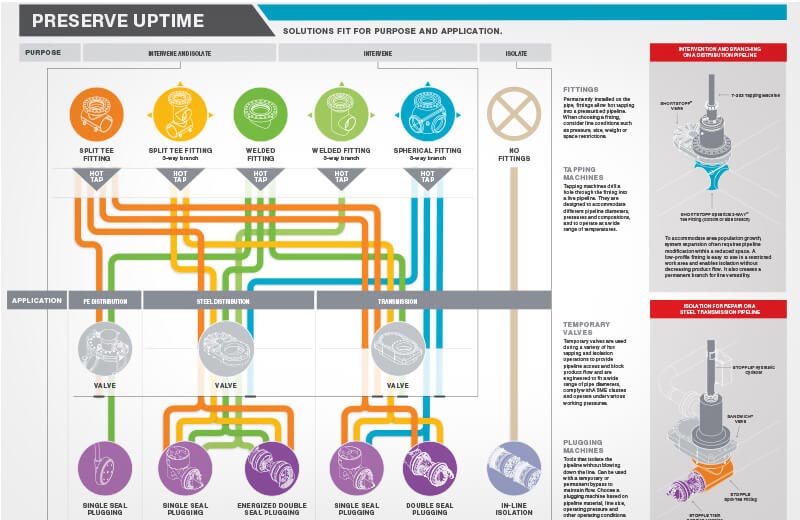

For decades, TDW has been a trusted source of advanced pipeline intervention and isolation equipment that meets the highest performance standards, including hot tapping machines, fittings, valves and plugging equipment.

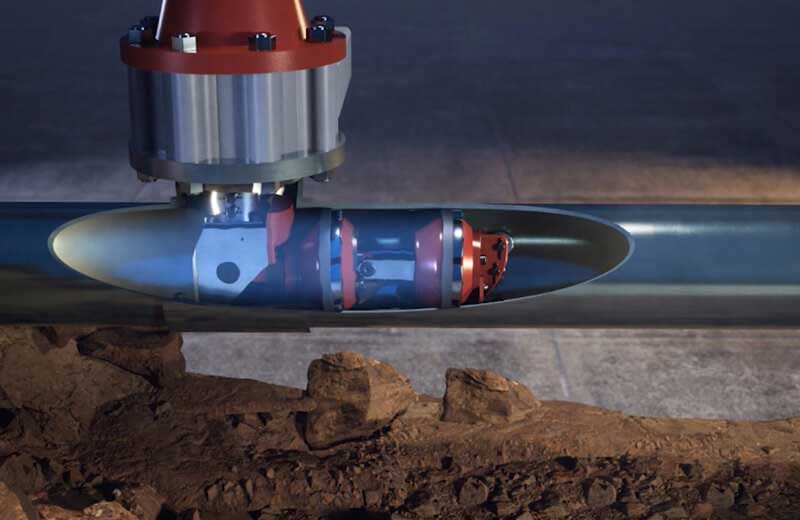

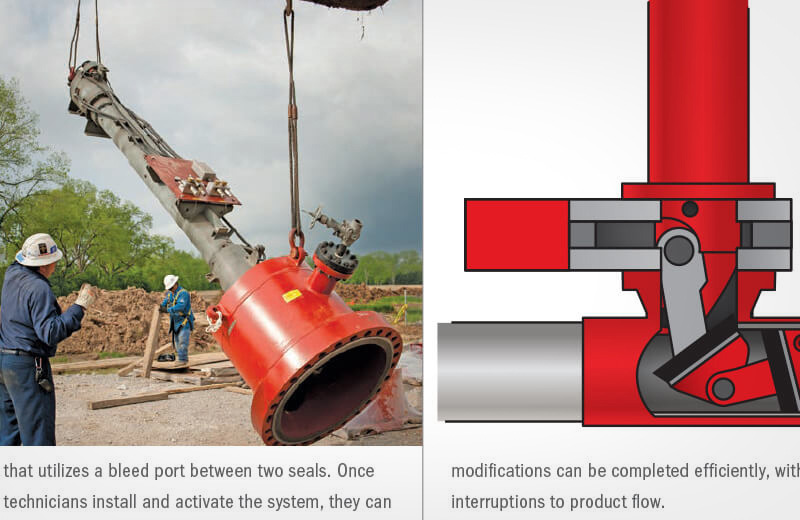

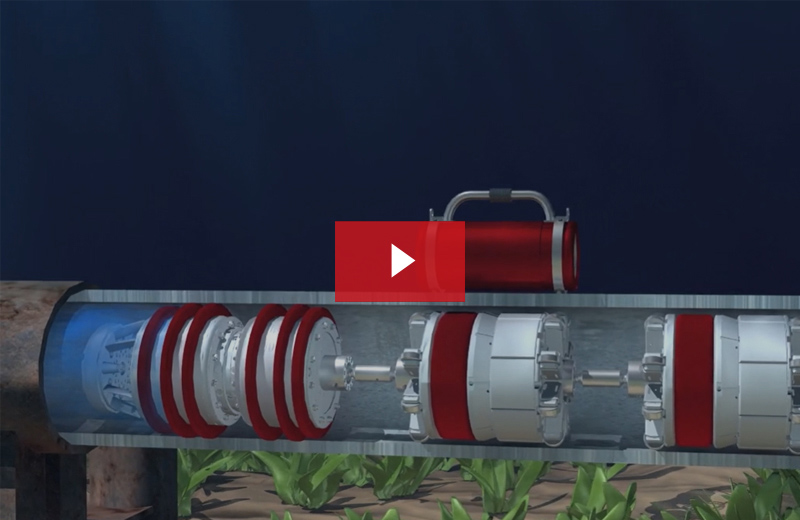

Hot tapping and plugging (HT&P) creates safe work zones during pipeline maintenance, modification and repair, without the time, risk or expense of shutting down the pipeline system. There’s no decommissioning or depressurization — meaning there’s no significant impact on product flow and emissions are reduced or eliminated. In fact, our traditional STOPPLE® pipeline isolation equipment keeps 97% of emissions per mile out of the atmosphere. Given that the STOPPLE system was introduced in 1953, it means our intervention and isolation solutions began helping operators meet environmental goals long before anyone had heard of the modern concept of sustainability.

As rules have gotten stricter and carbon reduction goals more aggressive, we’ve responded by further advancing our technologies. For example, by pairing traditional STOPPLE® isolation equipment with cross-compression technology, we’re providing an alternative to venting, flaring or blowdown that reduces methane emissions to nearly zero. That’s a powerful improvement and just the latest step in our never-ending commitment to sustainability-forward solutions.

Of course, any equipment is only as good as the people who operate it — and the TDW technicians who operate our equipment are thoroughly-trained professionals. Every one of them has completed comprehensive training and has proven themselves in tough jobs all over the world.