Pigging Services

Pipeline Cleaning

Although pipeline cleaning operations occur routinely, they can be complex — and they always require understanding of each pipeline’s unique characteristics. With experience cleaning onshore and offshore pipelines all over the world, we can recommend the optimal pigging equipment and schedule for your pipeline, including developing cleanliness metrics and progressive pigging programs to overcome reduced flow and maximize throughput.

General Consulting

Whether you need help pinpointing a problem or determining the optimum pigging option to address a need, TDW pigging experts will partner with you to develop a custom solution. With decades of experience manufacturing and running pigs, we can diagnose conditions in the pipeline system and develop an appropriate pigging response.

Pre-Construction Preparation

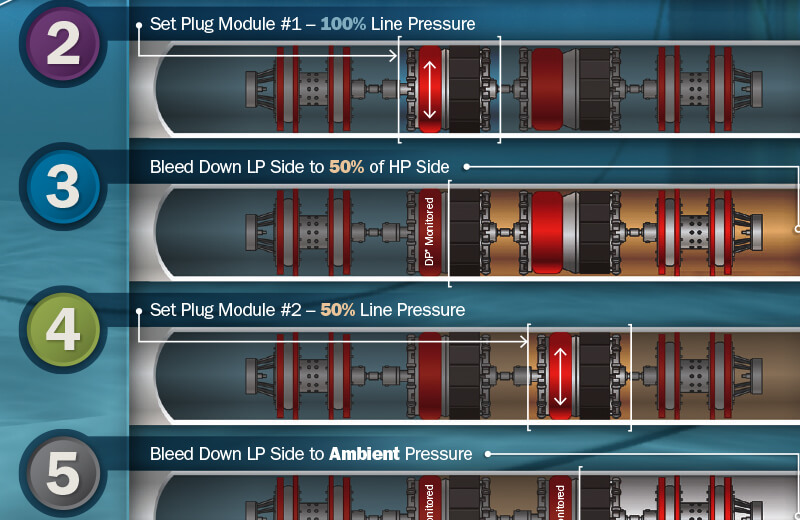

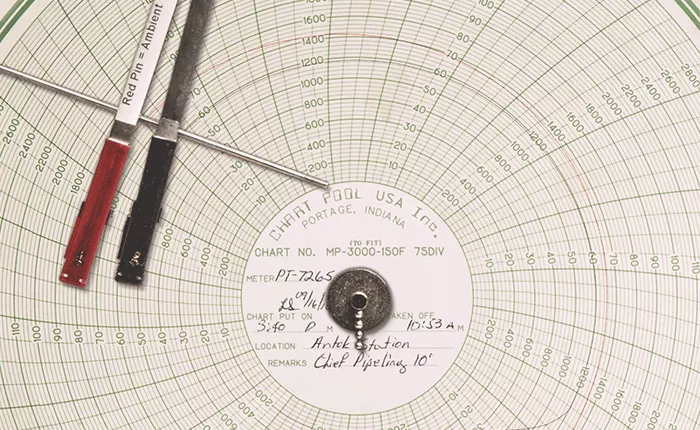

A mandatory party of the pre-commissioning process, hydrostatic testing is also performed on in-service pipelines. Pigging’s role is to ensure that the line is clean and that potentially damaging construction debris has been cleared away. Pigging is also used for line-filling and dewatering. TDW can help you about the right pigging equipment and services for each step of the hydrostatic testing process.

Pig Selection for Service

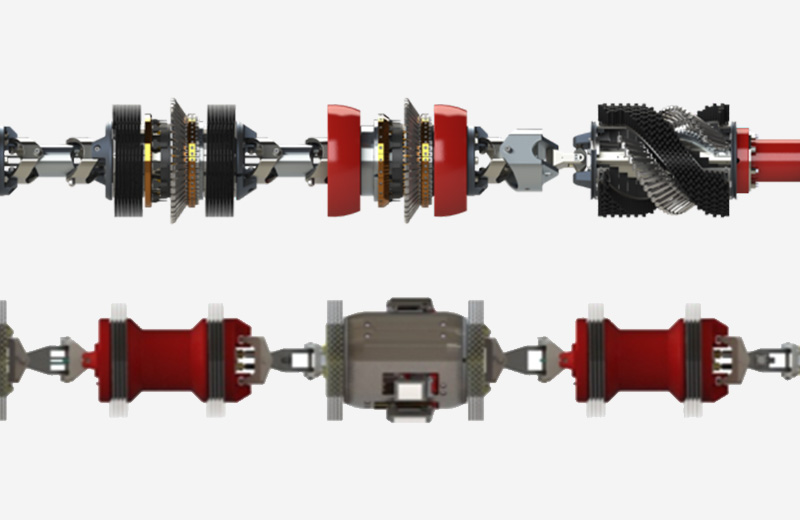

Selecting the right equipment is one of the most important steps operators can take to ensure a successful pipeline maintenance plan.

We’ll help you understand which TDW pig is best for your pipeline environment, size, product, goals and timeline.

Stuck Pig Response

Pigs are run successfully every day. However, every so often a pig becomes stuck, stalled or damaged inside the pipeline.

The pig removal process begins by understanding why the pig became stuck. Then TDW engineers develop customized recovery operations that take into consideration pig type, its location, pipeline product and other variables. The result? Safe removal, without product loss or asset damage.

Project Management

Pigging plays a role in everything from maintenance cleaning to detecting line obstructions. TDW experts can design a best practices pigging program aligned with your priorities. Working together, we’ll help you overcome challenges and meet your operating and integrity goals.