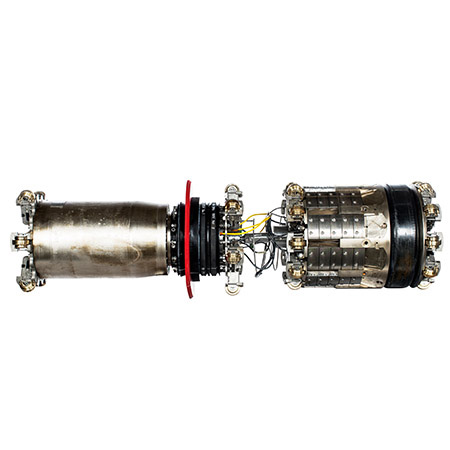

SmartPlug® Non-Intrusive Pipeline Isolation Tool

Equipment Type

Pressure/ANSI Class

Size

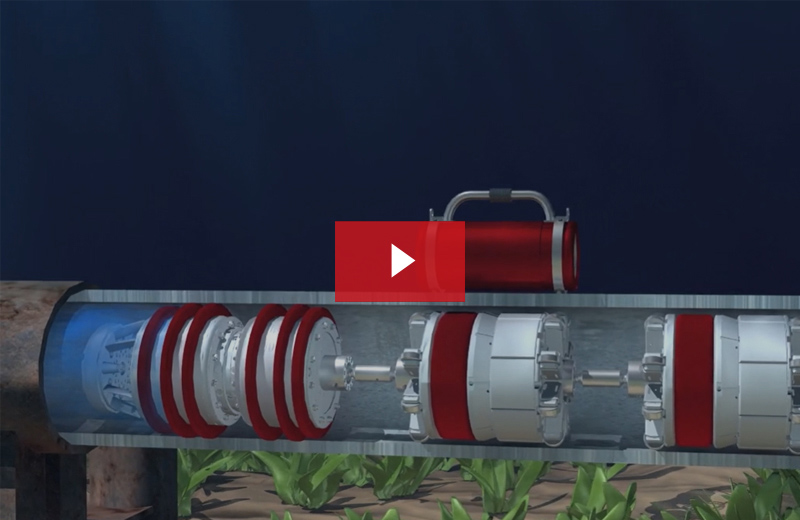

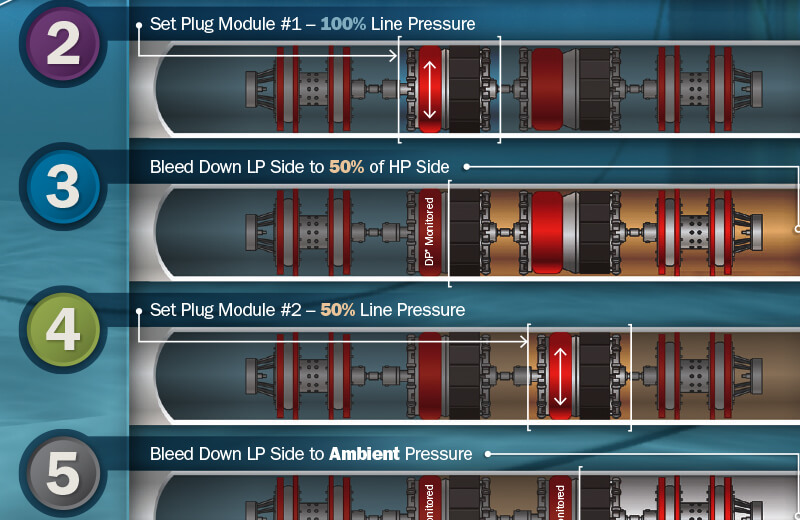

In its typical configuration, two plug modules work independently to isolate the full pipeline pressure alone, the SmartPlug® tool meets the accepted criteria for a true double block pipeline isolation — and it’s been field-proven in 300+ projects offshore and onshore, enabling operators to minimize downtime by performing repairs and maintenance without bleeding down the entire system. The integrity of each seal can be validated at all times by monitoring the annulus pressure between the two plug modules, representing a significant safety advantage.

Specifications

- Seals against up to 350 bar (5,075 psi) operating pressure

- 8-inch through 48-inch

Key Features

- Non-intrusive and tetherless

- Articulated modules are bi-directionally piggable

- Onboard control and communications

- Failsafe self-lock via differential pressure; additional built in contingency unsetting system

- ATEX Zone 1 Compliant equipment available

Common Applications

- Isolating offshore and onshore pipelines for planned maintenance and emergency repair work, including but not limited to valve replacement, riser and midline repair, tie-ins, dropped object protection during construction, hydrotesting and trap installation

In its typical configuration, two plug modules work independently to isolate the full pipeline pressure alone, the SmartPlug® tool meets the accepted criteria for a true double block pipeline isolation — and it’s been field-proven in 300+ projects offshore and onshore, enabling operators to minimize downtime by performing repairs and maintenance without bleeding down the entire system. The integrity of each seal can be validated at all times by monitoring the annulus pressure between the two plug modules, representing a significant safety advantage.

Equipment Type

Pressure/ANSI Class

Size

Specifications

- Seals against up to 350 bar (5,075 psi) operating pressure

- 8-inch through 48-inch

Key Features

- Non-intrusive and tetherless

- Articulated modules are bi-directionally piggable

- Onboard control and communications

- Failsafe self-lock via differential pressure; additional built in contingency unsetting system

- ATEX Zone 1 Compliant equipment available

Common Applications

- Isolating offshore and onshore pipelines for planned maintenance and emergency repair work, including but not limited to valve replacement, riser and midline repair, tie-ins, dropped object protection during construction, hydrotesting and trap installation