Mission

The TDW mission for the PETROSLEEVE® is to consistently deliver reliable, dependable and exceptional client services, produce high-quality, rigorously tested and meticulously documented products and continuously provide support and training to our incredibly valued employees.

Safety

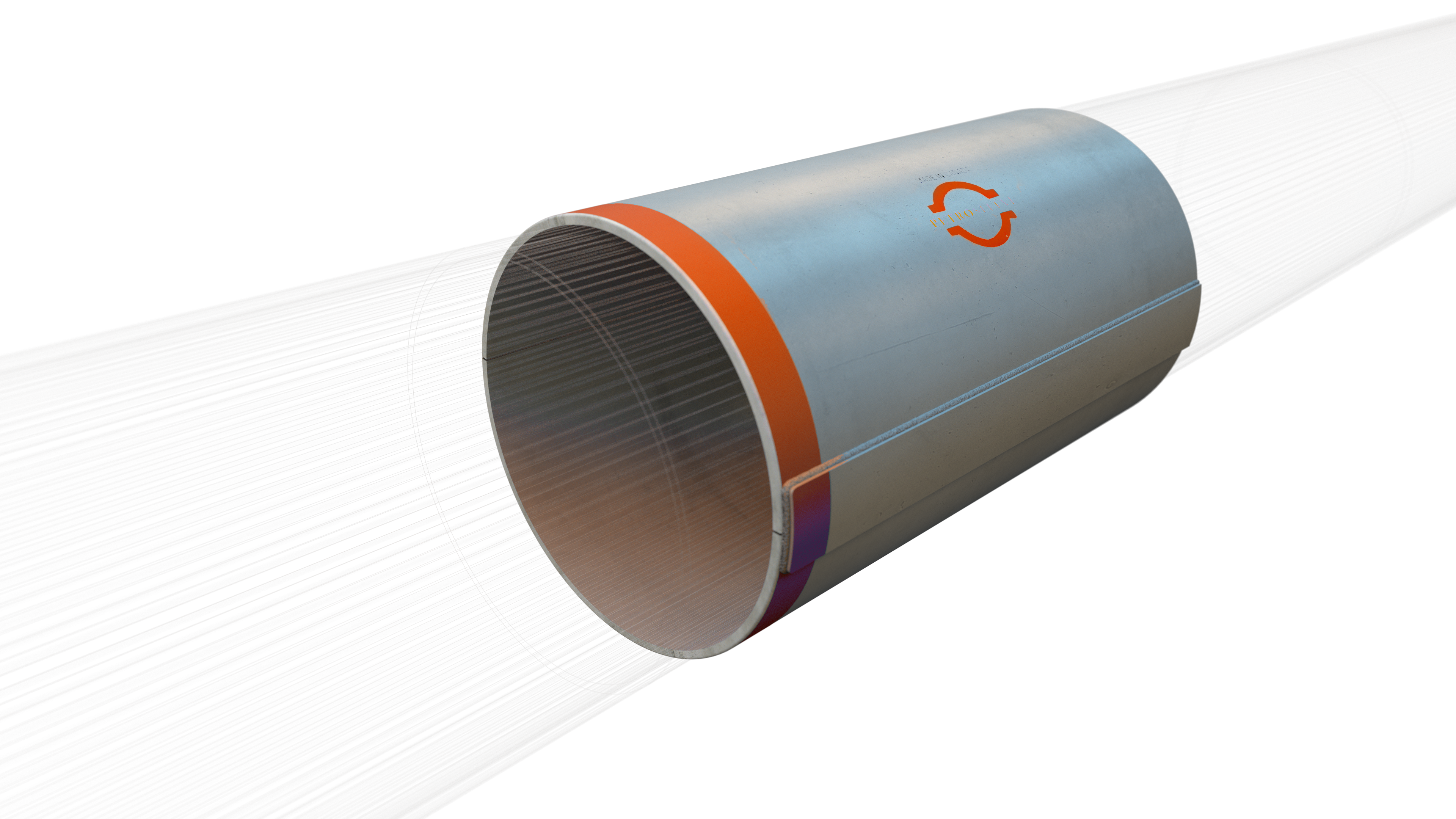

The PETROSLEEVE® or Type-C (compression) Pipeline Repair System promotes a safer site because no welding to the pipe surface removes concerns related to high CE, high strength steels, thin wall pipe sections, complex welding procedures, or finding landing areas for welds. The PETROSLEEVE® Pipeline Repair System will significantly reduce the risk of repairing defective pipelines while not affecting pipeline operations. The safety of every member of ours and your team is paramount in all installations.

Cost Evaluation

Using the PETROSLEEVE® Pipeline Repair System immediately reduces project costs. Alternative application options do not compete with our cost saving matrixes.

Immediate Savings: The PETROSLEEVE® offers cost savings on every installation. This is achieved in part because:

- Repairs occur while your pipeline remains in operation

- The immense costs of cut-out repairs are avoided

- You will easily repair more pipeline in less time

- PETROSLEEVE® eliminates lost production costs

- The completed repair is permanent

- Your repair budget is greatly extended

- Every sleeve comes with free analysis/quality online control software

- Free software reduces documentation costs

- The PETROSLEEVE® exceeds code requirements

Key Features

- Repair can be completed and ready for coating and backfill in less than 1 hour

- Permanently restores the integrity of the pipe.

- Complimentary (EIP) Engineering Installation Parameter software calculates installation requirements, and provides validation and documentation of successful installation.

- Testing continues to validate and expand the types of defects which can be permanently repaired using the PETROSLEEVE system.

- Maintains constant compression on the carrier pipe and never disbands from the pipeline.

- Prevents pipeline failure and arrests any defect growth.

- Used to repair corrosion, cracks, dents, gouges and various other construction and mill defects.

History

The PETROSLEEVE® was conceived after the industry required a permanent repair solution following an increased discovery of significant Stress Corrosion Cracking (SCC). It was first installed in Canada.

The vision for the compression sleeve is to immediately reduce project costs for our clients, promote site safety through low-risk pipeline repair options that prevent pipeline failures and to provide repair solutions that reflect client, community and environmental values.

After the installation of a PETROSLEEVE®, the pipeline owner can immediately confirm that their repair criteria has been achieved. You can have confidence in choosing the PETROSLEEVE® Pipeline Repair System as your pipeline repair method, knowing that zero failures have been reported for any installed PETROSLEEVE®.

Cost and Safety Comparison: In a simple study reviewing both Cost Factor and Safety Risks inherent different methods of repairing defects, the PETROSLEEVE® clearly demonstrated immediate and cumulative project cost savings.

Complimentary Engineering Installation Parameters (EIP) software calculates installation requirements, validates installation, and provides post-repair documentation.

Today, with more than 60,000 Type-C sleeve installations worldwide, this is truly the industry's gold standard in pipeline repair.

PETROSLEEVE® Specifications

Specifications - overview

- Diameters: NPS 2 (60.3mm) to NPS 48 (1524mm)

- Length (individual PETROSLEEVE®): 36 (914MM) (Shorter sections could be prepared on site)

- Thickness: 0.200" (5.156mm) to 2" (50.8mm)1

- Pipeline temperature range: 0 degrees C (32 degrees F) to 50 degrees C (122 degrees F)1

Specifications - design and quality control

- Sleeve material: pipeline grade carbon steel

- Manufacturing: individual quality control documentation (strict tolerance standards) and material testing records (MTR's)

- Engineering design: custom engineering design with post-installation validation report on every sleeve

- Epoxy durability: high strength, high modulus, moisture insensitive and high bond epoxy (cures and performs at install and pipeline operating temperatures)

Specifications - application history

- Total successful installs: 63,000+

- Years in service: 30+ years

- In-service failures: Zero

- Applicable to pipeline products (but are not limited to): crude oil, natural gas, sour natural gas and HV

Tools & Accessories

Small Diameter (NPS 28 and smaller)

- Small Diameter Clamp Tool Kit (Less than NPS 30 Diameter): engineered clamps and tools used to assemble small diameter sleeves at the repair location during installation.

- Installation Kit: each purchased PETROSLEEVE® comes with an installation kit containing a 2-part epoxy, disposable mixing tools, and clean-up tools necessary during installation.

- QC Measurement Kit: a complete kit for measuring installation parameters of the PETROSLEEVE®.

- Hoist Bars (Less than NPS 30 Diameter): sold as a set of two bars that assist in raising the lower half of the PETROSLEEVE® into position.

Large Diameter (NPS 30 and larger)

- Large Diameter Clamp Tool Kit (NPS 30 Diameter and greater): engineered clamps and tools used to assemble large diameter sleeves at the repair location during installation.

- Large Diameter Heating Units: specialized Heating Units are required for the Large Diameter PETROSLEEVE® installations.

- Hoist Cradle (Greater than NPS 30 Diameter): the Hoist Cradle comes as a unit and assists in raising the lower half of a large diameter PETROSLEEVE® into position when it cannot be managed safely by hand.

- Propane Basket: the propane basket allows the storage of the necessary propane supplied in a single basket to the Heating Units.

- Worktable: the worktable is sold as an organization table that will rest on top of the pipeline to store the unique tools, clamps, and propane controllers required for a large diameter installation.

PETROSLEEVE® in the field: Case Study

Showcasing the Best Pipeline Repair Solution

TDW's Harold Lee and Blake Knowles discuss the PETROSLEEVE during the Permian Basin International Oil Show Podcast

Take the Next Step Toward Permanent Pipeline Repair

Discover how PETROSLEEVE® can be your solution to pipeline repair needs.