SMARTLAY™ System

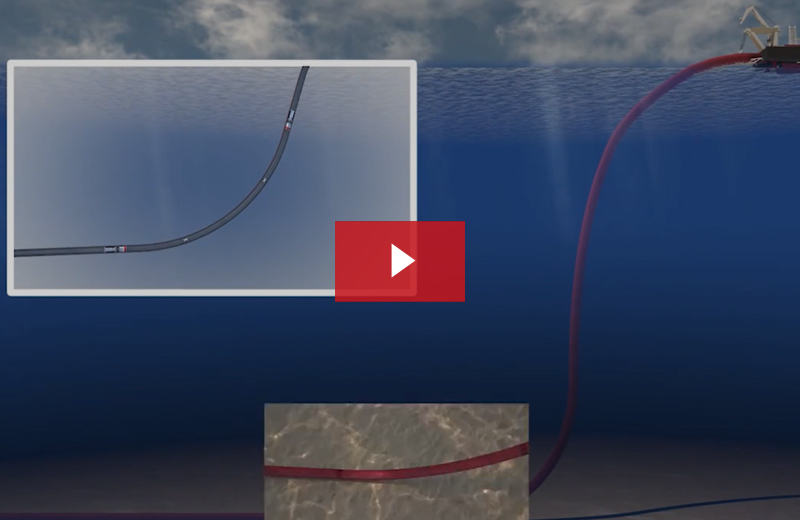

By preventing pipeline flooding as a result of wet buckle during offshore pipe lay operations, the SmartLay™ system mitigates risk to the pipe lay vessel and crew, and also protects as-laid pipeline and helps eliminate costs associated with standby dewatering spreads.

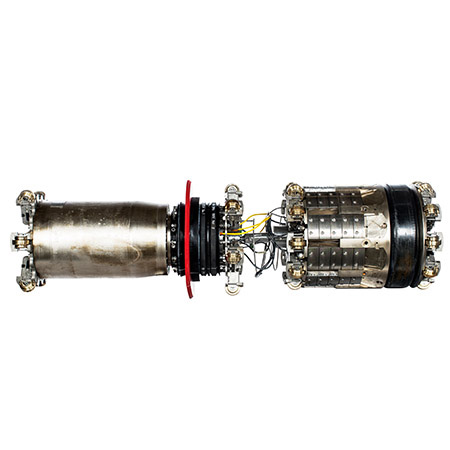

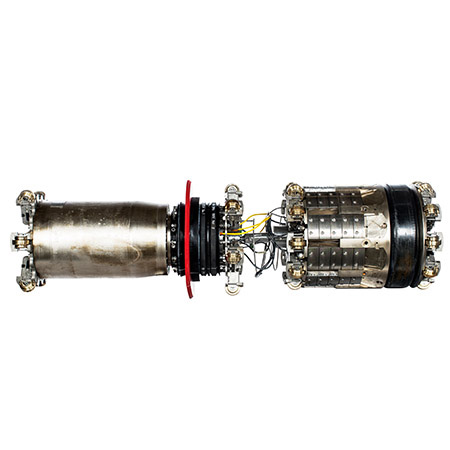

The SmartLay tool and operational processes rely on field-tested, DNV GL-approved SmartPlug® isolation technology.

Specifications

- Usable for all typical deep water pipelays

Key Features

- Can be used in either shallow or deep waters

- Plug module activates rapidly, typically in less than one second, when saltwater or pressure are detected

- Customizable to meet project requirements. Up to three tools can be deployed at any position in the pipeline at any one time

- Operates automatically and independently of lay vessel

- Interfaces with client-supplied towing and communication arrangements

- Functions with either a cable/umbilical or a remotely operated pulling device

- Can be set and unset multiple times without recovering the equipment to the surface

- Communicates and allows remote monitoring of operational conditions through the use of an umbilical or a SmartTrack™ system transceiver

- Easy to operate directly from an onboard laptop operated through a Graphical User Interface (GUI)

Common Applications

- Supporting offshore pipe laying operations

By preventing pipeline flooding as a result of wet buckle during offshore pipe lay operations, the SmartLay™ system mitigates risk to the pipe lay vessel and crew, and also protects as-laid pipeline and helps eliminate costs associated with standby dewatering spreads.

The SmartLay tool and operational processes rely on field-tested, DNV GL-approved SmartPlug® isolation technology.

Specifications

- Usable for all typical deep water pipelays

Key Features

- Can be used in either shallow or deep waters

- Plug module activates rapidly, typically in less than one second, when saltwater or pressure are detected

- Customizable to meet project requirements. Up to three tools can be deployed at any position in the pipeline at any one time

- Operates automatically and independently of lay vessel

- Interfaces with client-supplied towing and communication arrangements

- Functions with either a cable/umbilical or a remotely operated pulling device

- Can be set and unset multiple times without recovering the equipment to the surface

- Communicates and allows remote monitoring of operational conditions through the use of an umbilical or a SmartTrack™ system transceiver

- Easy to operate directly from an onboard laptop operated through a Graphical User Interface (GUI)

Common Applications

- Supporting offshore pipe laying operations