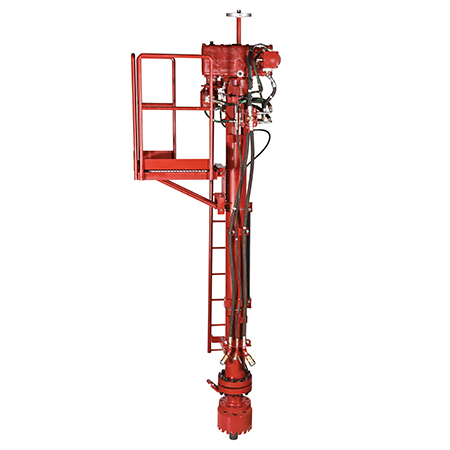

936 XL Tapping Machine

Equipment Type

Pressure/ANSI Class

Size

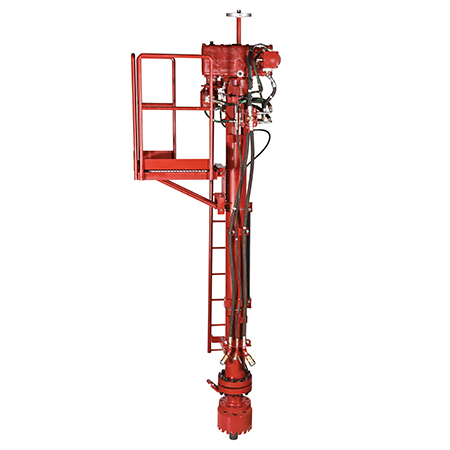

Engineered for a wide variety of applications and environments where pipelines cannot be shut down, the TDW 936 tapping machine can be used for hot taps and for setting completion plugs, including LOCK-O-RING® and LOCK-O-RING Plus. The machine is especially design for high pressure applications up to 153 bar (2220 psi).

Specifications

- 12-inch through 42-inch (DN 300 to DN 1000) taps

- Maximum working pressure: 153 bar (2,220 psi) at 38°C (100°F)

- Operating temperature range: -18°C to 82°C (0°F to 180°F) at 153 bar (2,220 psi)

- 106 inch boring bar travel (exist also with 130 inch boring bar travel)

- Fixed feed rate: 0.004-inch per revolution

- Available with hydraulic systems and TDW power unit

Key Features

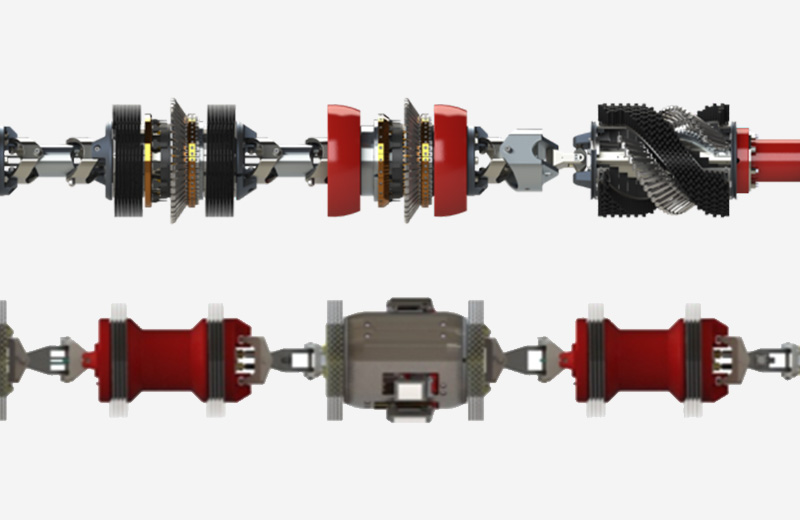

- Split frame design that lowers maintenance costs and provides ease of packing replacement

- Pressure balance system - with Compensation cylinders - that equalize pipeline pressure and reduce stress on internal component, extending tapping machine life

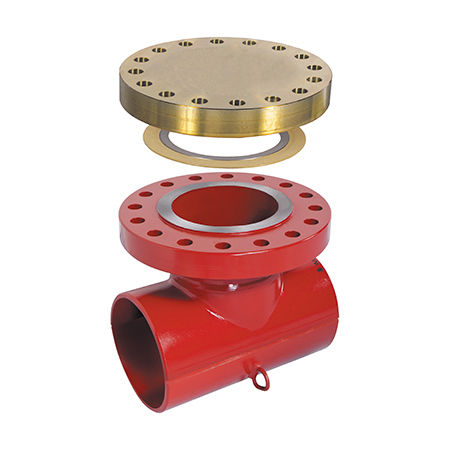

- Supplied with accessories as measuring rod, ring gasket, bleeder valve, set of bolts, etc.

- Skid is available for safe storage and handling

Common Applications

- Making pipeline and tank taps for tie-in or Isolation intervention

- Setting completion plugs

Engineered for a wide variety of applications and environments where pipelines cannot be shut down, the TDW 936 tapping machine can be used for hot taps and for setting completion plugs, including LOCK-O-RING® and LOCK-O-RING Plus. The machine is especially design for high pressure applications up to 153 bar (2220 psi).

Equipment Type

Pressure/ANSI Class

Size

Specifications

- 12-inch through 42-inch (DN 300 to DN 1000) taps

- Maximum working pressure: 153 bar (2,220 psi) at 38°C (100°F)

- Operating temperature range: -18°C to 82°C (0°F to 180°F) at 153 bar (2,220 psi)

- 106 inch boring bar travel (exist also with 130 inch boring bar travel)

- Fixed feed rate: 0.004-inch per revolution

- Available with hydraulic systems and TDW power unit

Key Features

- Split frame design that lowers maintenance costs and provides ease of packing replacement

- Pressure balance system - with Compensation cylinders - that equalize pipeline pressure and reduce stress on internal component, extending tapping machine life

- Supplied with accessories as measuring rod, ring gasket, bleeder valve, set of bolts, etc.

- Skid is available for safe storage and handling

Common Applications

- Making pipeline and tank taps for tie-in or Isolation intervention

- Setting completion plugs