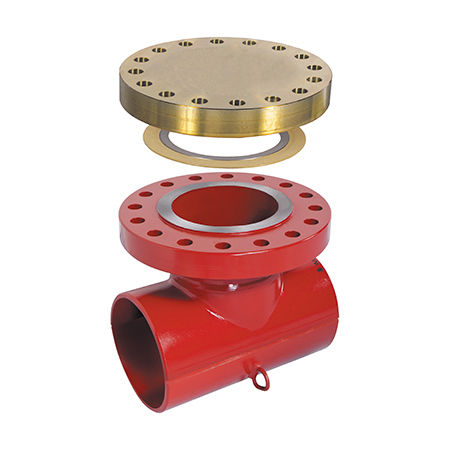

Tapping Fitting

Equipment Type

Pressure/ANSI Class

Size

Designed to meet the specific requirements of branch line installation, TDW tapping fittings are available in a wide range of sizes and both full-branch and reduced-branch configurations. All fittings are manufactured with a controlled carbon equivalent to make welding in harsh environments easier.

Specifications

- 2-inch through 108-inch.

- Pipe type: Carbon steel, cast iron, ductile iron, concrete, etc.

- ANSI flange class 150, 300, 600, 900, 1500, and 2500.

- ASME codes B31.1, B31.3, B31.4, B31.8, and CSA Z662 CAT I and II. EN standards also available.

- Maximum allowable operating pressure: Can be fully rated for each ANSI class.

- Temperature -45°C to 649°C (-50°F to 1200°F).

- Fitting type: Split tee, full-branch and reduced branch.

- Alternative tapping styles – Spherical tees, Welded fittings, Mechanical sleeves, 3-WAY tees.

Key Features

- Most fittings are manufactured from a pressure-vessel quality, normalized, killed-carbon steel plate with hardness below Rc22(for NACE compliance).

- All TDW tapping fittings undergo radiographic inspection in accordance with ASME requirements.

- Multiple sleeve material options are available to meet the unique demands of different applications.

Common Applications

- Installing branch connections.

- Custom applications can be designed upon request.

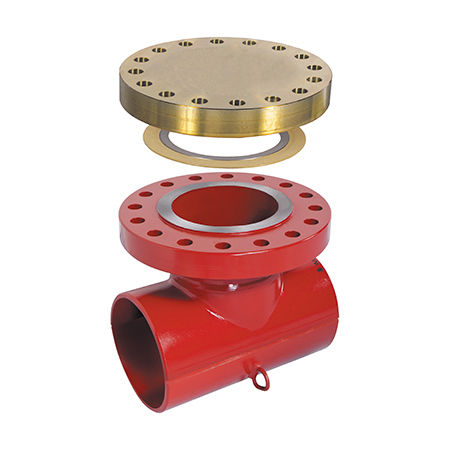

Designed to meet the specific requirements of branch line installation, TDW tapping fittings are available in a wide range of sizes and both full-branch and reduced-branch configurations. All fittings are manufactured with a controlled carbon equivalent to make welding in harsh environments easier.

Equipment Type

Pressure/ANSI Class

Size

Specifications

- 2-inch through 108-inch.

- Pipe type: Carbon steel, cast iron, ductile iron, concrete, etc.

- ANSI flange class 150, 300, 600, 900, 1500, and 2500.

- ASME codes B31.1, B31.3, B31.4, B31.8, and CSA Z662 CAT I and II. EN standards also available.

- Maximum allowable operating pressure: Can be fully rated for each ANSI class.

- Temperature -45°C to 649°C (-50°F to 1200°F).

- Fitting type: Split tee, full-branch and reduced branch.

- Alternative tapping styles – Spherical tees, Welded fittings, Mechanical sleeves, 3-WAY tees.

Key Features

- Most fittings are manufactured from a pressure-vessel quality, normalized, killed-carbon steel plate with hardness below Rc22(for NACE compliance).

- All TDW tapping fittings undergo radiographic inspection in accordance with ASME requirements.

- Multiple sleeve material options are available to meet the unique demands of different applications.

Common Applications

- Installing branch connections.

- Custom applications can be designed upon request.