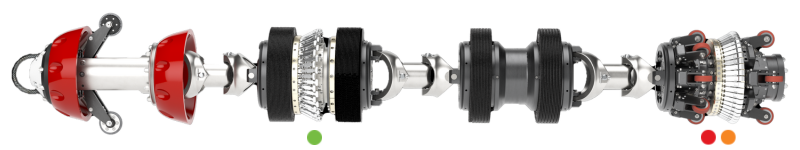

MDS™ Flex Platform

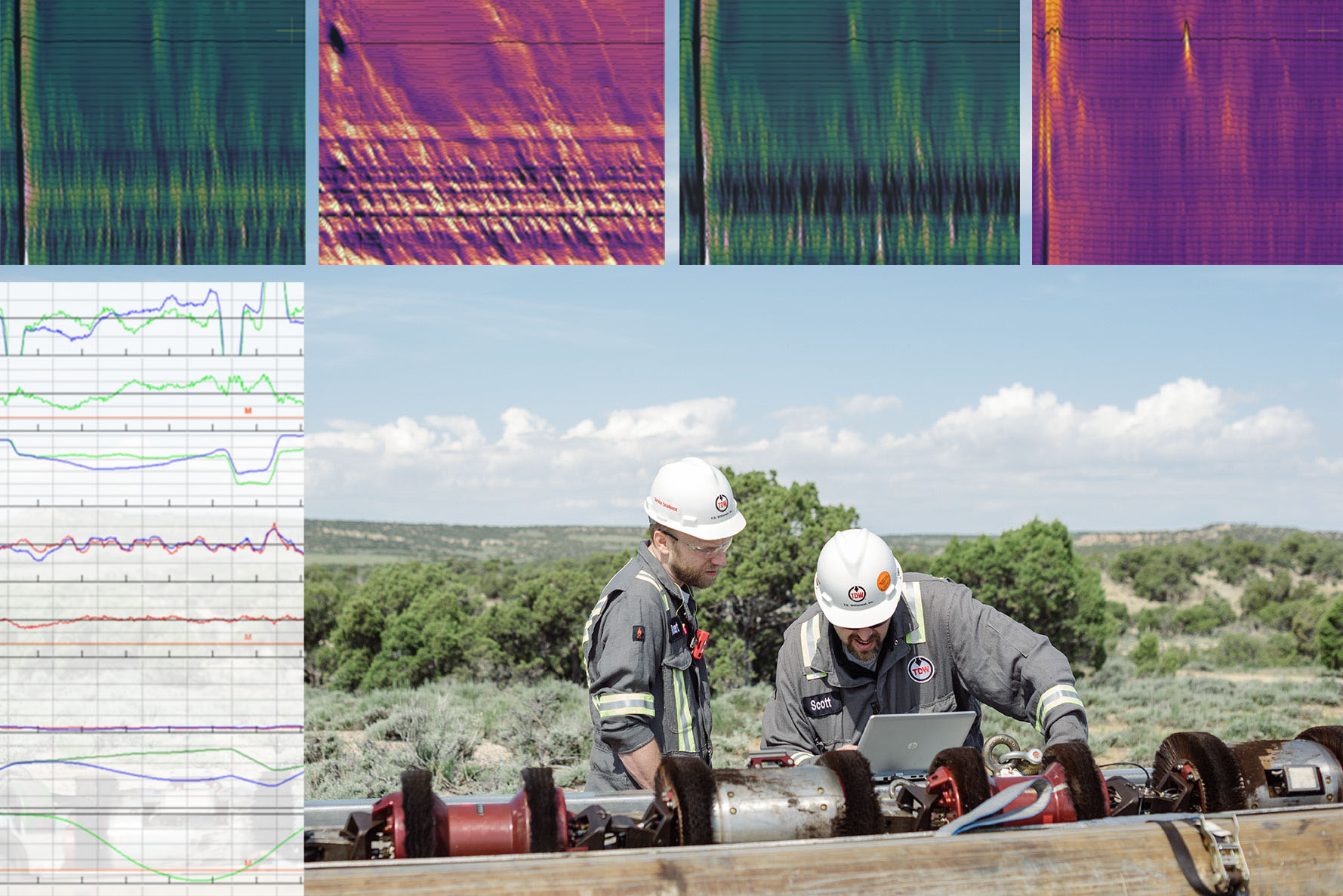

MDS™ Flex closes the detection gaps left by single ILI tools by integrating multiple in-line inspection (ILI) technologies on a single platform. The MDS Flex is a shorter, more versatile configuration of our MDS Pro tool, which is designed to meet the specific needs of our customers, offering adaptability without compromising on performance.

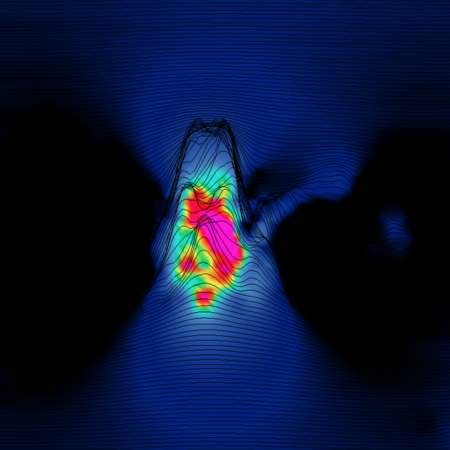

The updated MDS Flex with Ultra Res MFL technology expands the detection capabilities of the tool even further. Ultra Res MFL brings the highest density of axial MFL sensors, enhancing detection performance for pinhole anomalies, complex corrosion and other threats.

Key Features

- Offers versatility and adaptability, allowing operators to target specific threats.

- Now with Ultra Res MFL technology, resulting in enhanced pinhole sizing and additional insight into complex corrosion.

- Shorter tool that can be customized to fit your needs.

- Empowers run comparison with either a previous MDS Pro or MDS Flex inspection.

Technologies

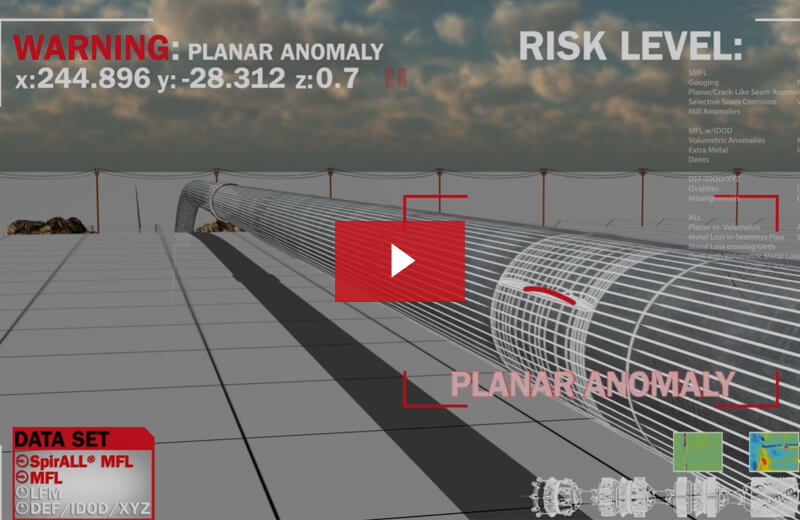

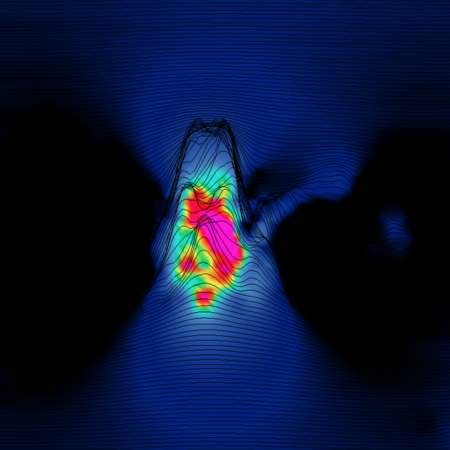

Ultra Res Magnetic Flux Leakage (MFL)

Detects, identifies and sizes metal loss and circumferential planar anomalies.

Low Field MFL (LFM)

Identifies material property changes resulting from manufacture, milling or mechanical working.

XYZ Mapping (XYZ)

Measures pipe centerline, provides highly accurate coordinates for all reported features, and enables bending strain analysis.

Deformation (DEF)

Detects, identifies and sizes bore changes such as dents, ovalities, expansions and wrinkles.

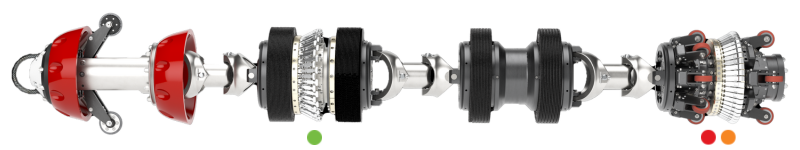

MDS™ Flex closes the detection gaps left by single ILI tools by integrating multiple in-line inspection (ILI) technologies on a single platform. The MDS Flex is a shorter, more versatile configuration of our MDS Pro tool, which is designed to meet the specific needs of our customers, offering adaptability without compromising on performance.

The updated MDS Flex with Ultra Res MFL technology expands the detection capabilities of the tool even further. Ultra Res MFL brings the highest density of axial MFL sensors, enhancing detection performance for pinhole anomalies, complex corrosion and other threats.

Key Features

- Offers versatility and adaptability, allowing operators to target specific threats.

- Now with Ultra Res MFL technology, resulting in enhanced pinhole sizing and additional insight into complex corrosion.

- Shorter tool that can be customized to fit your needs.

- Empowers run comparison with either a previous MDS Pro or MDS Flex inspection.

Technologies

Ultra Res Magnetic Flux Leakage (MFL)

Detects, identifies and sizes metal loss and circumferential planar anomalies.

Low Field MFL (LFM)

Identifies material property changes resulting from manufacture, milling or mechanical working.

XYZ Mapping (XYZ)

Measures pipe centerline, provides highly accurate coordinates for all reported features, and enables bending strain analysis.

Deformation (DEF)

Detects, identifies and sizes bore changes such as dents, ovalities, expansions and wrinkles.