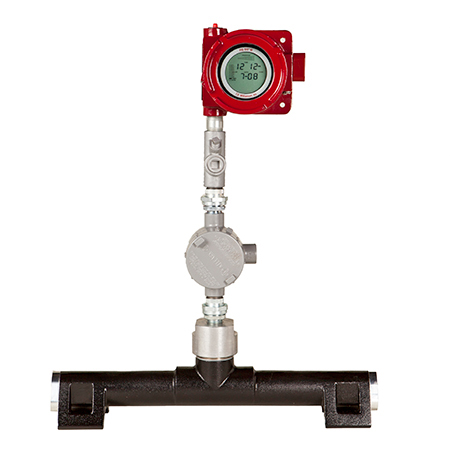

Pig passage indicators are commonly referred to as “PIG-SIGs,” a term TDW originated more than 60 years ago. They accurately detect pigs, spheres, scrapers, and other tools as they pass distinct points along the pipeline and when they reach the receiver, and can also alert operators if a pig is lost or stuck.

The weatherproof and corrosion-resistant PIG-SIG® V pig passage indicator is built to withstand the most brutal environments, both onshore and topside. In addition, all components exposed to pipeline products are completely sealed to prevent leaks.

Key Features

- Omnidirectional trigger.

- Pig Sig can be installed in any direction, and it will work properly.

- Operator can perform maintenance on the Pig Sig while the line is under pressure. It can be removed under pressure using the T-101. Maintenance includes replacing the filter pack, magnet, changing the flag, etc.

- The operator doesn't need to blow down the line to perform maintenance.

- Weatherproof and corrosion-resistant, all stainless-steel components.

- Can be used in a wide variety of applications.

- Electric version can connect to operator's SCADA system.

- Can be tracked as a total pipeline operation.

- Different configurations

- Wide range of applications.

Common Applications

- Accurately detecting, signaling, and recording the passage of pigs and other tools at predetermined intervals along a pipeline

Pig passage indicators are commonly referred to as “PIG-SIGs,” a term TDW originated more than 60 years ago. They accurately detect pigs, spheres, scrapers, and other tools as they pass distinct points along the pipeline and when they reach the receiver, and can also alert operators if a pig is lost or stuck.

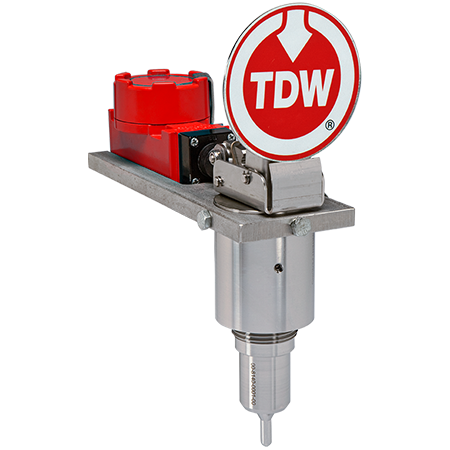

The weatherproof and corrosion-resistant PIG-SIG® V pig passage indicator is built to withstand the most brutal environments, both onshore and topside. In addition, all components exposed to pipeline products are completely sealed to prevent leaks.

Key Features

- Omnidirectional trigger.

- Pig Sig can be installed in any direction, and it will work properly.

- Operator can perform maintenance on the Pig Sig while the line is under pressure. It can be removed under pressure using the T-101. Maintenance includes replacing the filter pack, magnet, changing the flag, etc.

- The operator doesn't need to blow down the line to perform maintenance.

- Weatherproof and corrosion-resistant, all stainless-steel components.

- Can be used in a wide variety of applications.

- Electric version can connect to operator's SCADA system.

- Can be tracked as a total pipeline operation.

- Different configurations

- Wide range of applications.

Common Applications

- Accurately detecting, signaling, and recording the passage of pigs and other tools at predetermined intervals along a pipeline