2

Case Study

PETROSLEEVE®... the answer for rapid pipeline integrity restoration

TDW Offering: Repair Solution

Technology: PETROSLEEVE® or Type C-sleeve (compression)

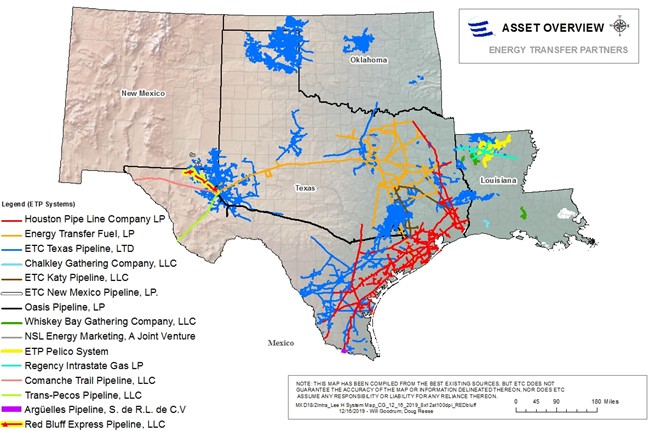

Project Location: Texas

Pipeline challenge detected

The client identified SCC (Stress Corrosion Cracking) and DSAW (Double Submerged Arc Weld) defects in the pipeline. Timely repair of these defects was critical to ensure system integrity under normal operating conditions. These defects appeared across 13 sites on a 36-inch diameter pipeline operating at ~820 psig. Traditional repair methods using Type B sleeves could have potentially taken up to five weeks.

Goal for Repair Solutions team

The objective going into the jobsites was to restore pipeline integrity quickly and safely, minimize downtime and disruption to gas flow and ensure regulatory compliance.

Solution for job:

- 22 PETROSLEEVE® installations were completed in four total days.

- Utilized three welding crews for simultaneous operations.

Tool application:

- NPS 36x1" thick x 36" long.

- Material: A516-70.

Execution

Highlights:

- Coordinated logistics across multiple sites.

- Streamlined communications between field crews and engineering teams.

Results:

- 90% reduction in repair time compared to traditional methods.

- Zero safety incidents reported.

- Maintained pipeline throughput and avoided costly shutdowns.

- Enhanced client confidence in PETROSLEEVE® as a rapid repair solution.

Client Impact

The success of this project showcased PETROSLEEVE®’s proven efficacy as the smart, cost-effective, and superior repair solution. Delivering unmatched savings for clients’ Southeast Texas Pipeline System. It also demonstrated the value of integrating repair technologies with strategic communications and project coordination.