Static and Cyclical Cracks Assessment

Are Cracks Appearing?

Cracks are often present in pipelines from manufacturing, transportation and operation. Many cracks and crack-like features may be innocuous, but under significant pressure cycles or environmental conditions, cracking can pose an increased threat to pipeline integrity. TDW assessments are designed to help operators detect, size and characterize cracks — and then assess their criticality for further investigation or repair.

Prioritizing Cracks and Crack-Like Features

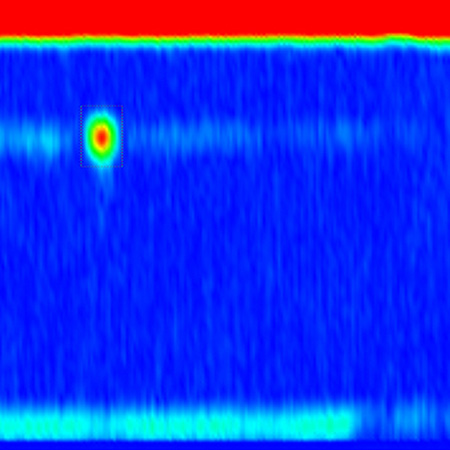

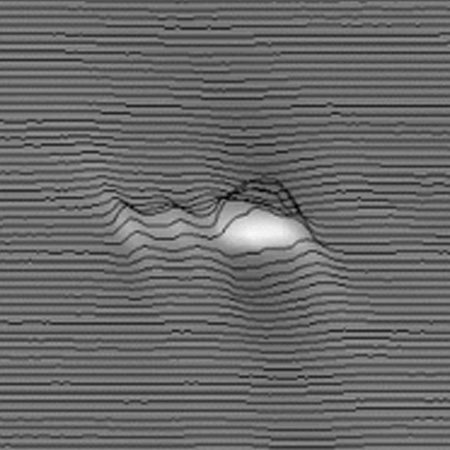

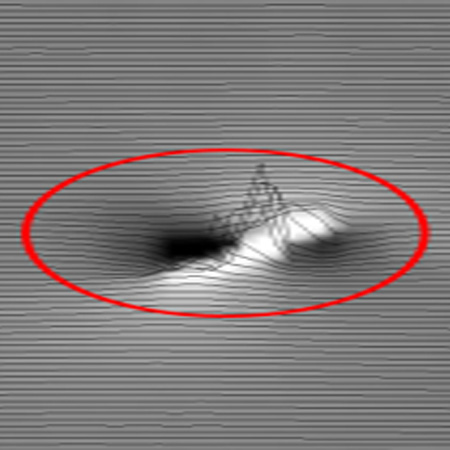

TDW utilizes two types of in-line inspection (ILI) technology, our electromagnetic acoustic transducer (EMAT) for true cracks and our MDS™ platform for crack-like features such as hook cracks and sharp-sided corrosion. TDW takes all datasets and can provide a prioritized list of anomalies that require further assessment or repair.

Approach

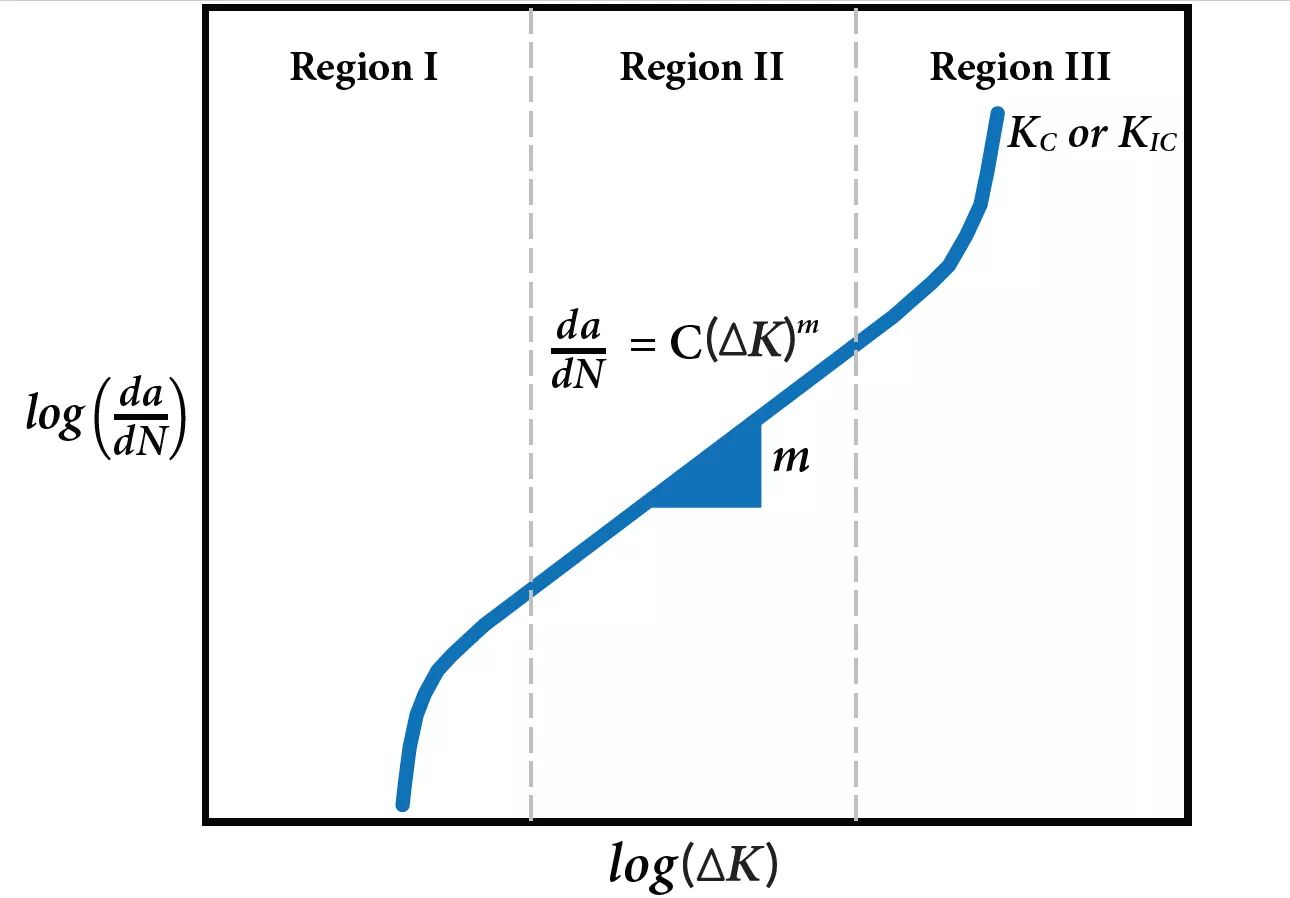

Crack Priority to Failure Assessment

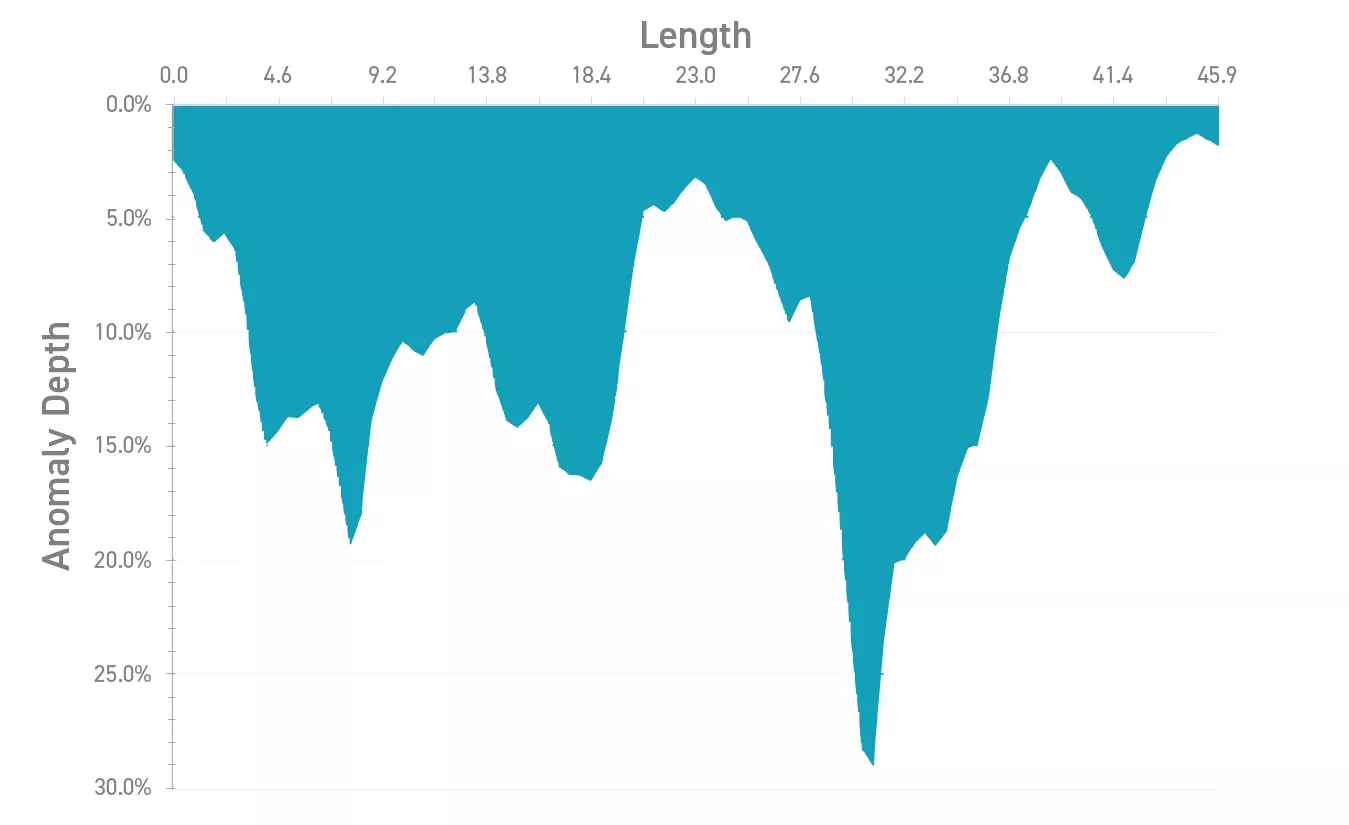

We use current industry-accepted approaches to prioritize all crack anomalies and then assess each crack, investigating the crack profile, material properties and loading, to provide a failure prediction and hence a safe working pressure or recommended repair action.

Value

Focusing on the Right Crack Features

We focus on the critical few crack features that require attention and help operators make decisions on immediate and future repairs, thus minimizing the threat and optimizing expenditure.