SpirALL® Electromagnetic Acoustic Transducer (EMAT)

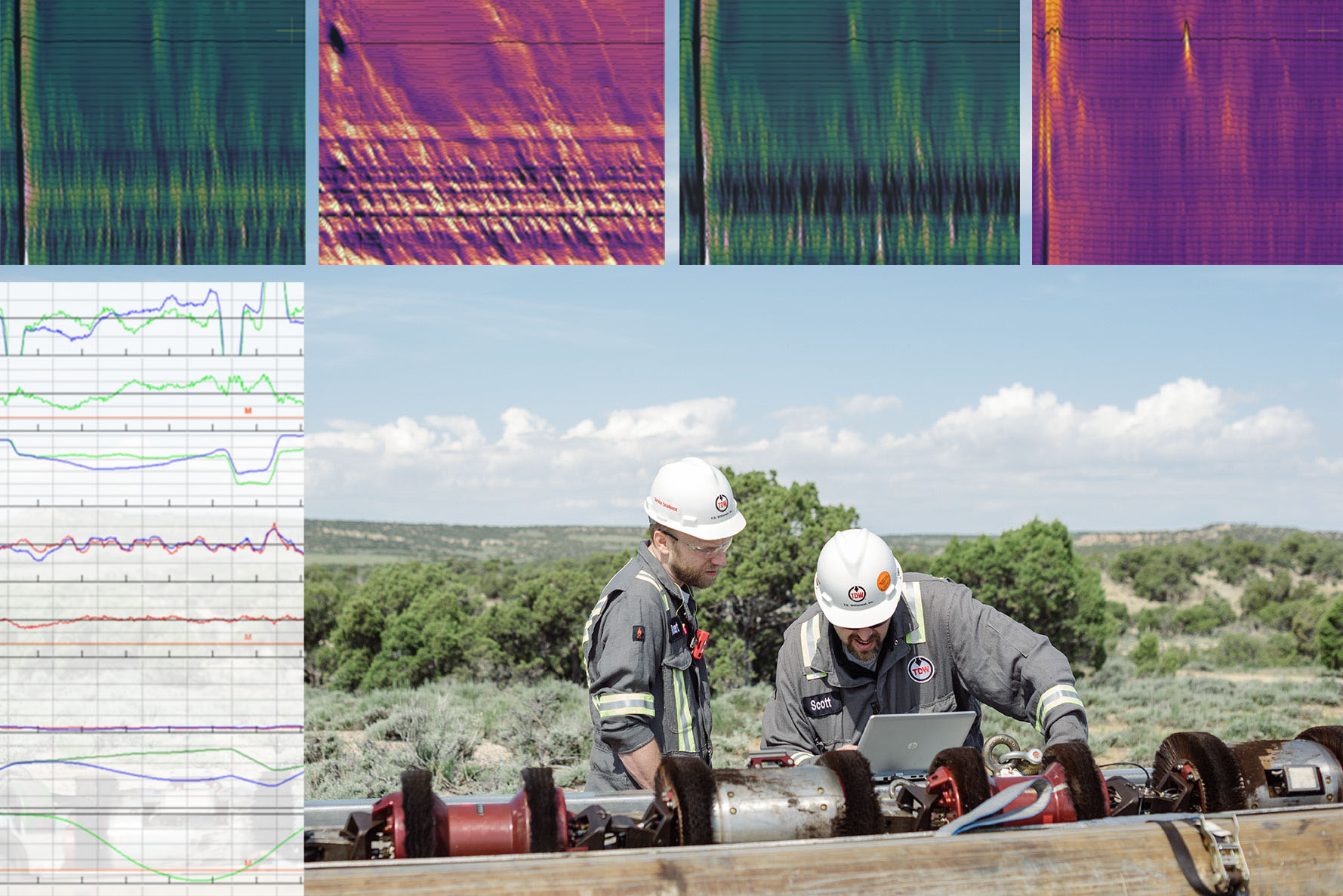

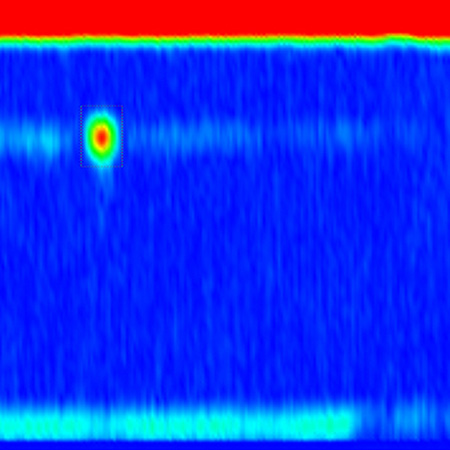

Designed to enhance in-line inspection and give pipeline owners and operators more confidence about inspection results for crack detection, SpirALL® Electromagnetic Acoustic Transducer (EMAT) technology finds anomalies that magnetic flux leakage-based technology is unable to detect.

SpirALL EMAT technology can be used in either liquid or gas pipelines without requiring a couplant.

Combining SpirALL EMAT data with data produced by the various technologies on the MDS™ (Multiple Datasets) platform enables more accurate characterization of pipeline defects.

Key Features

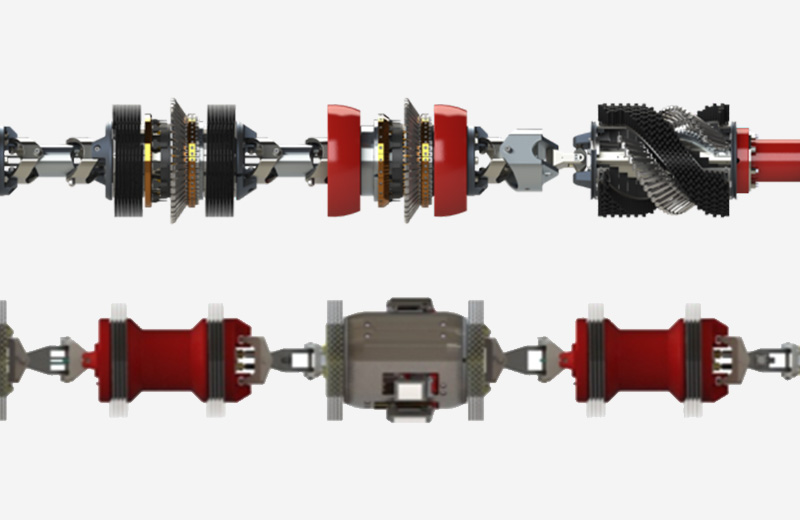

- Innovative design produced redundant data across multiple channels to reduce the likelihood of false or irrelevant data being erroneously recorded as a defect

- Data correlation with MDS eliminates false calls for non-critical features and delivers all pipeline features and anomalies in a single report

Sizes

- 10-inch through 16-inch

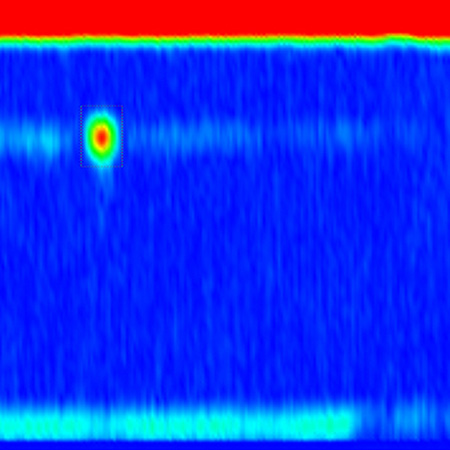

Designed to enhance in-line inspection and give pipeline owners and operators more confidence about inspection results for crack detection, SpirALL® Electromagnetic Acoustic Transducer (EMAT) technology finds anomalies that magnetic flux leakage-based technology is unable to detect.

SpirALL EMAT technology can be used in either liquid or gas pipelines without requiring a couplant.

Combining SpirALL EMAT data with data produced by the various technologies on the MDS™ (Multiple Datasets) platform enables more accurate characterization of pipeline defects.

Key Features

- Innovative design produced redundant data across multiple channels to reduce the likelihood of false or irrelevant data being erroneously recorded as a defect

- Data correlation with MDS eliminates false calls for non-critical features and delivers all pipeline features and anomalies in a single report

Sizes

- 10-inch through 16-inch