Other Services

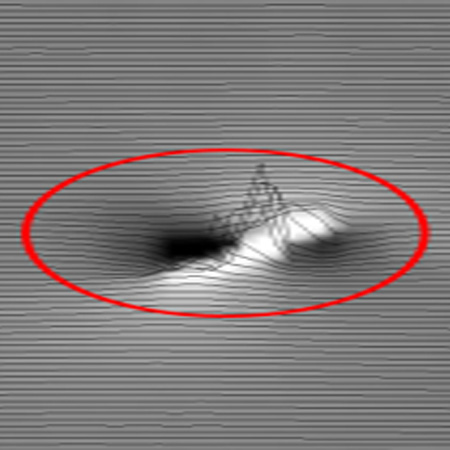

Acid Etch

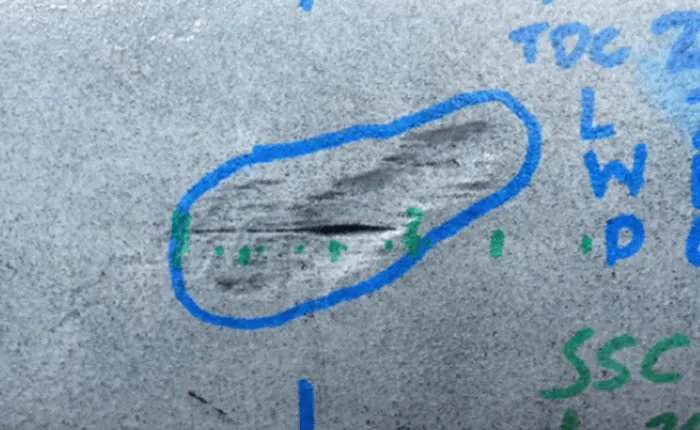

Acid etch is used to visualize and evaluate indications and locations of pipe features, including arc burns, welds, and other anomalies. That includes microstructure variations that may require detailed evaluation via additional NDE techniques.

- Determines heat affected zones in ERW weld seams

- Identifies localized hard spots

- Removes weld splatter, arc strikes and other material smear that can affect accurate feature evaluation

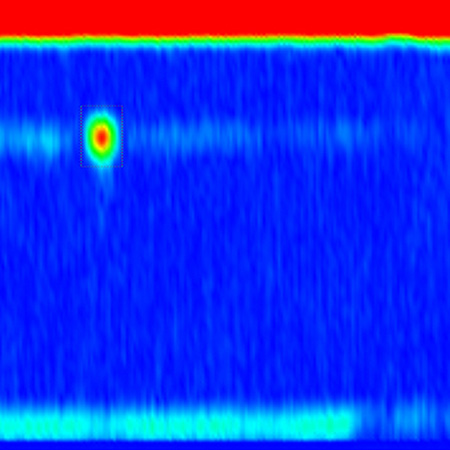

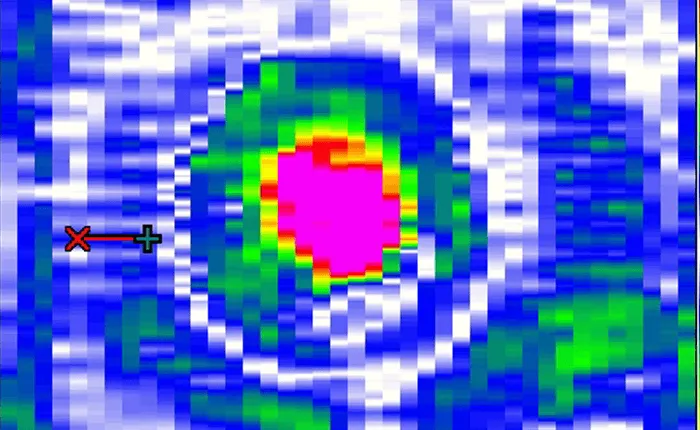

Eddy Current Array

Eddy current array (ECA) technology provides a highly sensitive means of detecting loss of thickness and surface flaws before commissioning and pipelines are in service. Minimal surface preparation is required, contributing to process speed and cost effectiveness. Because of the relatively simple scan patterns ECA produces, data analysis is quick and easy.

- Rapidly inspects large surface areas in a single pass, identifying cracks, corrosion and stress or permeability changes caused by dents

- Provides a permanent record of scan data

Magnetic Particle Testing

A combination of two non-destructive evaluation methods – magnetic flux leakage testing and visual inspection – magnetic particle inspection is used to check in-situ exposed pipe for surface anomalies such as stress corrosion cracking, hook cracks and lack of fusion. The part being inspected must be made of a ferromagnetic material such as iron, nickel, cobalt or some of their alloys.

- TDW offers fluorescent magnetic particle capabilities for a more sensitive inspection or for when the pipe is sweating and testing cannot be accomplished with dry powder

Weld Profile

Manual profile gauge provides direct measurements of metal loss, dents, gouges and other deformations on the pipeline’s surface. The gauge is capable of reaching deep within pits and deformations and can measure depths up to 25mm (1 inch) deep with +/- 0.0005 inch accuracy.

- Suitable for all pipeline sizes

- Can be used in even rugged conditions and environments