Circumferential Stress Corrosion Cracking Assessment

Prioritizing Potential Threats

Circumferential stress corrosion cracking (CSCC) is more difficult to detect with traditional in-line inspection tools than axial SCC, but it is just as harmful to pipeline integrity. Using advanced tools such as the MDS™ platform, TDW integrity engineers can help operators prioritize potential CSCC threats to investigate before leaks occur.

Causes of CSCC

Because SCC occurs more often, it is better understood by steel pipeline operators. But today, more and more operators are becoming aware of the threat that CSCC poses and how it can go undetected by traditional in-line inspection tools. Steel pipelines where the right conditions are present for SCC may develop CSCC when exposed to geohazards or extreme weather that causes bending strain. Circumferential SCC cracks can also occur due to settling or installation issues that change the orientation of the predominant load.

Threat Awareness: CSCC

In this video, Jason Matocha and Jonathan Hardy dive into Circumferential Stress Corrosion Cracking, sharing more about what causes CSCC and how TDW leverages our MDS™ Platform to help operators prioritize potential CSCC locations for investigation and remediation.

Approach

Combining Technologies for Complex Threats

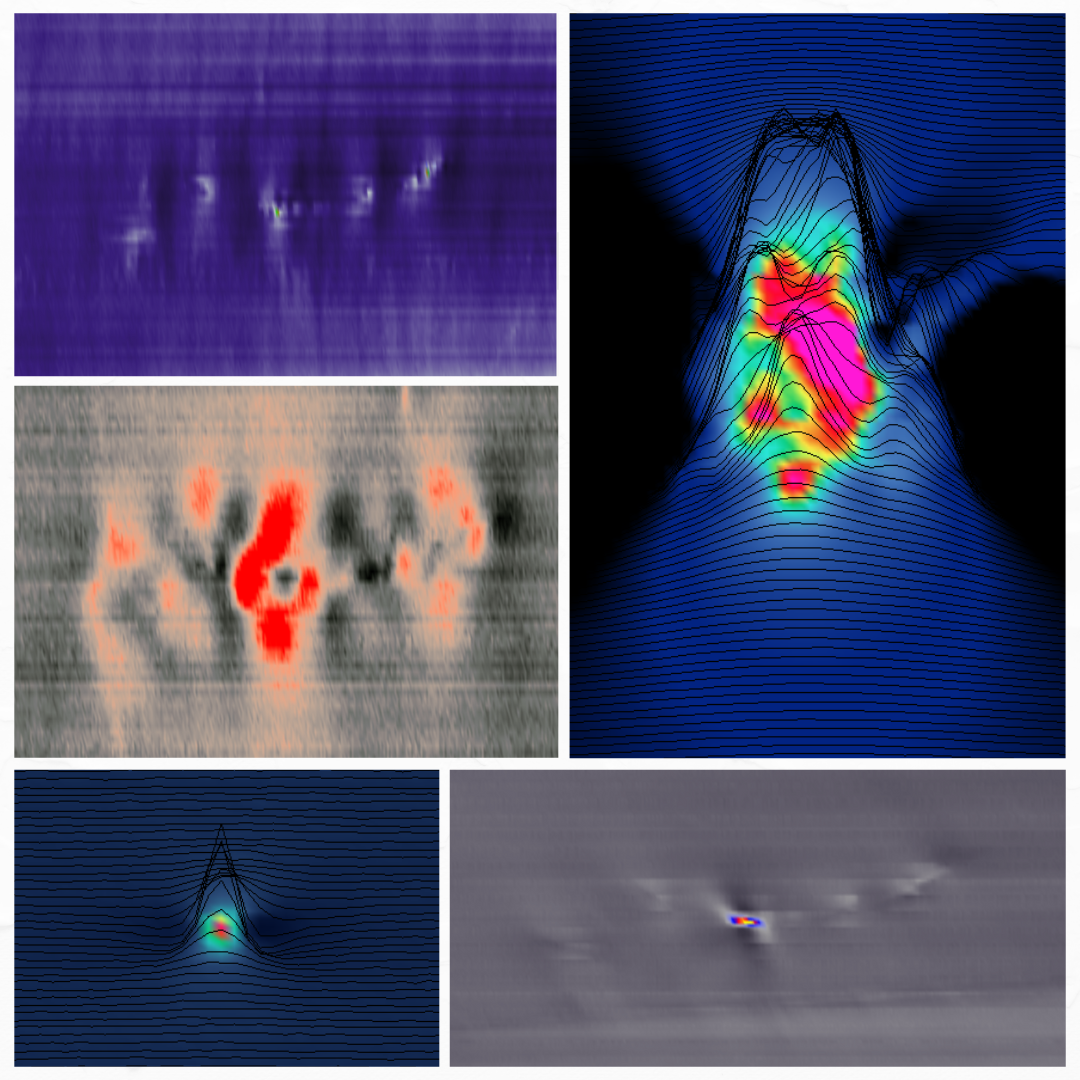

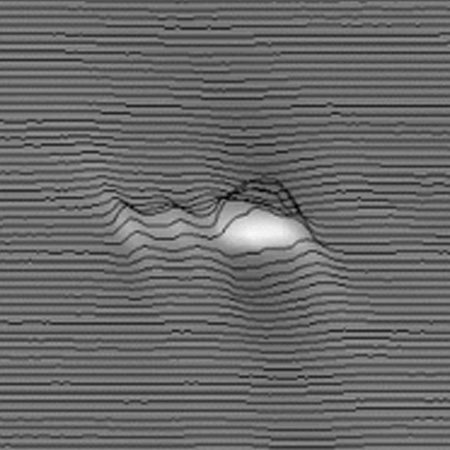

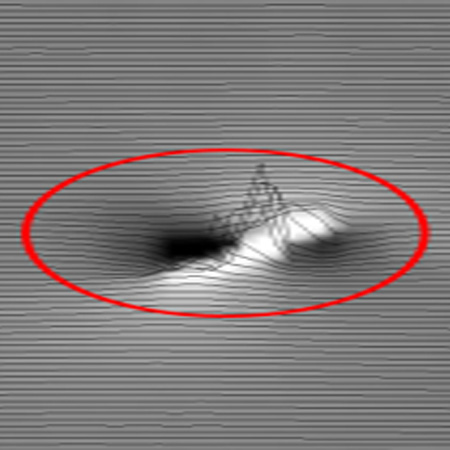

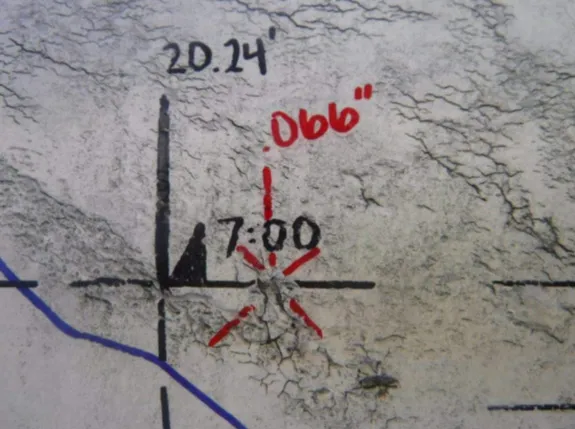

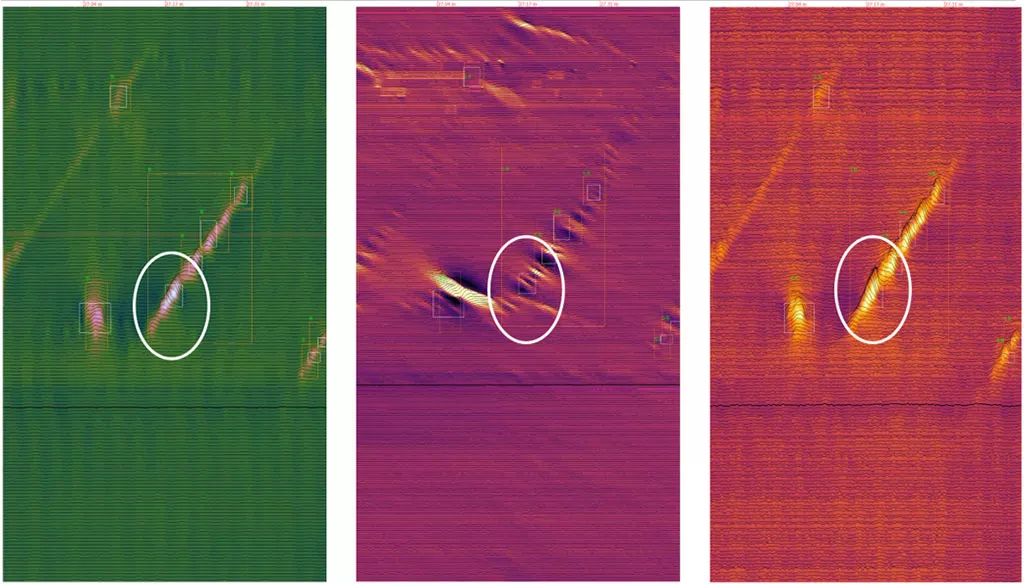

Leveraging a combination of ILI technologies, TDW Integrity engineers use MDS™ platform data to identify pipeline locations with active corrosion and concentrated tensile stresses due to unexpected pipeline bending.

Value

Prioritizing Threat Locations

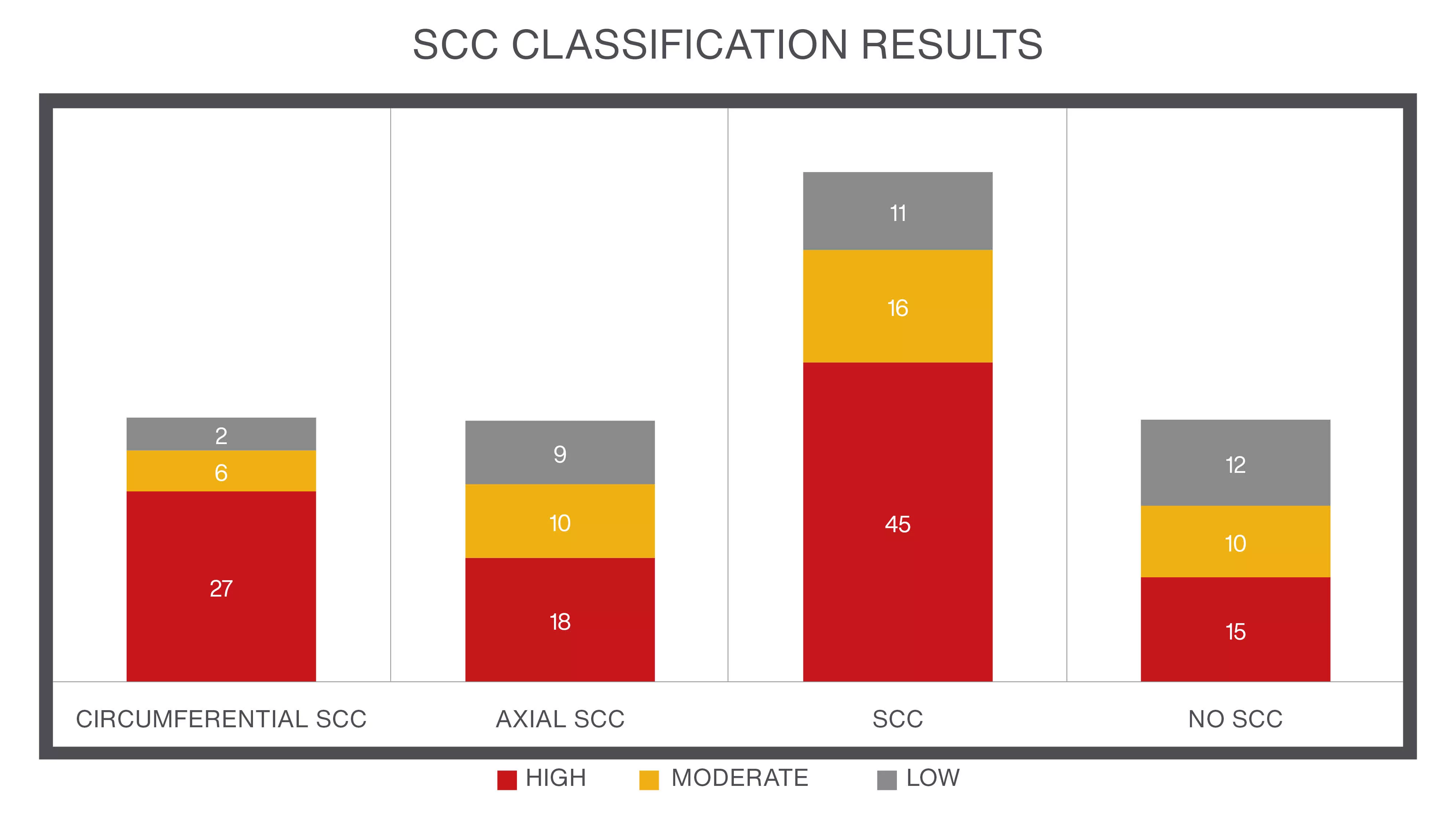

Based on their analysis, our team of TDW integrity engineers classify each location as low, moderate, or high potential for SCC or CSCC. These locations are further prioritized using an associated scoring model to deliver a report that aids in planning digs or repair operations.