2

Article

SHiiELD™ is a new, safer and leak-proof class of double independent isolation technology

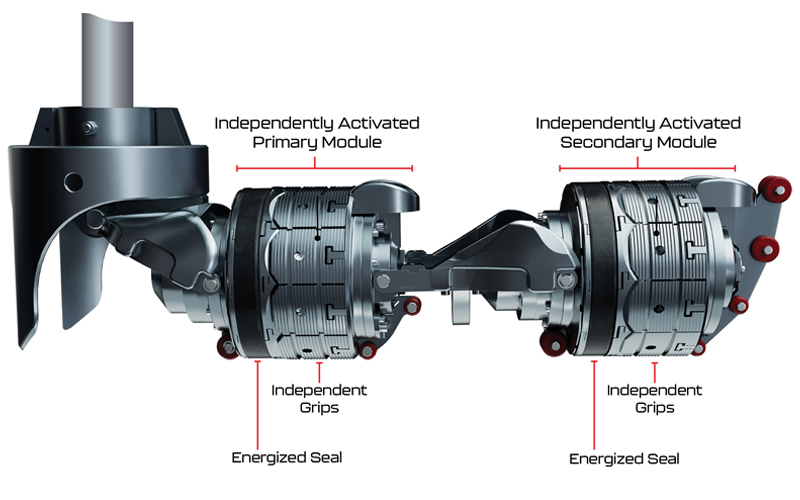

After decades of mastering pipeline isolation and field-proven engineering, T.D. Williamson (TDW) has innovated and delivered SHiiELD™, the first double independent isolation and bleed system with fully remote operation. Built with energized sealing, electromechanical activation, and rigorous quality control, SHiiELD gives operators unmatched confidence, verified leak-proof isolation, and operational control that transforms the way pipelines are maintained and repaired.

From high-pressure transmission lines to critical gathering systems, SHiiELD turns complex, high-risk operations into safer, faster, and more predictable jobsites while redefining industry expectations for isolation technology.

Pipeline crews rely on tools that combine experience, precision, and safety. Double barriers are essential for preventing hazardous product release during maintenance. With SHiiELD, each barrier operates independently with verified pressure sealing, remote activation, and real-time monitoring. Redundancy is no longer symbolic; it is measurable and documented, giving operators the assurance they need in every operation.

Isolation methods such as double block and bleed (DBB), double isolate and bleed, and double block and monitor have long been used in the industry. SHiiELD establishes a new benchmark by delivering fully independent, energized sealing with integrated remote operation, turning years of field experience and customer feedback into a single system that sets the standard for 2026 and beyond.

How regulators define double block and bleed pipeline isolation

Safety, compliance and environmental protection guide every isolation decision. DBB technology has delivered reliable performance for decades, yet definitions vary across regulatory frameworks.

- American Petroleum Institute (API 6D) defines DBB as a single valve with two seating surfaces that seal pressure from both ends with a cavity that can bleed.

- Occupational Safety and Health Administration (OSHA) defines DBB as closing and tagging two inline valves and opening the vent valve between them.

- Pipeline and Hazardous Materials Safety Administration (PHMSA) references DBB concepts throughout pipeline safety regulations. but does not offer a formal definition.

Canada Energy Regulator (CER) / Canadian Standards Association (CSA align with industry best practices and lean on engineering expertise.

Across these agencies, the shared intent is clear. DBB safeguards crews, mitigates risk and verifies isolation before intrusive work begins.

Understanding double isolate and bleed (DIB) and double block and monitor (DBM) tools

Plugging tools like TDW’s STOPPLE® Train have long served transmission and distribution operators who need double block and bleed protection. These tools are proven, yet definition for DIB and DBM shift between regions and operators.

DIB uses two pressure-retaining barriers with a monitored bleed point between them.

DBM uses two sealing elements with continuous monitoring of the annulus to spot leakage past the primary seal.

Both approaches increased safety, yet field experience showed they were steppingstones. Operators wanted true independence between sealing elements to match the evolving risk environment.

Why distinguishing block versus isolate improves pipeline safety

Operators often use “block” and “isolate” interchangeably, but they are different:

- A block is a physical boundary that stops flow.

Isolation creates the pressure anchor across the barrier.

Traditional DBB tools depend on a shared pressure body. A problem inside that body can compromise both seals. In aging assets where unknown ID anomalies or uneven pressure gradients appear, that shared anchor becomes a vulnerability.

Double independent isolation and bleed changes the equation. Each module has its own activation mechanism, holds its own anchor and seals at full pressure independently. Redundancy becomes functional instead of symbolic.

TDW SHiiELD double independent isolation and bleed technology combines the safety of DIB with significant improvements

Leveraging decades of field experience, engineering expertise, and a deep understanding of operator needs, TDW has innovated and delivered the first system with double independent isolation and bleed technology that can be fully operated remotely. SHiiELD is the culmination of our industry knowledge, designed to provide verified, leak-proof isolation while keeping technicians safely outside the ditch, redefining what is possible in pipeline maintenance and repair.

Key features include:

Patented energized grip technology that evenly distributes anchor stress for reliable sealing.

Certified leak-proof seal performance that eliminates fugitive emissions.

Remote activation allowing crews to control operations from a safe distance.

SmartTrack real-time monitoring that documents seal performance, pressure behavior, and procedural compliance.

Integrated bypass delivering up to four times the throughput of legacy systems without pressure derating.

Compatibility with standard fittings for rapid deployment and reduced downtime.

SHiiELD transforms pipeline operations, creating a safer, cleaner, and more predictable work environment while proving that innovation in isolation technology is both practical and operationally superior.

How isolating instead of shutting down pipelines reduces downtime and emissions

By relying on double independent isolation and bleed rather than full shutdowns, operators reduce downtime, limit product venting, and maintain operational flow. SHiiELD allows teams to execute intrusive maintenance safely and efficiently, while minimizing environmental exposure and operational interruptions.

Benefits include:

Reduced product venting during repairs

Fewer system interruptions.

Less environmental impact.

More reliable project timelines.

By combining independent sealing with remote activation and digital verification, SHiiELD establishes a new standard for pipeline safety and efficiency.

Why double independent isolation and bleed is the next-generation standard for pipeline isolation

Choosing the right isolation method depends on fluid behavior, operational risk, and project demands. SHiiELD removes shared pressure components and anchors each module independently, delivering:

Higher redundancy.

Improved environmental protection.

Greater operational control.

Reduced exposure for personnel.

By combining independent sealing with remote activation and digital verification, SHiiELD establishes a new standard for pipeline safety and efficiency.

TD Williamson delivers innovative solutions for safer and more efficient pipeline operations

Backed by more than a century of innovation, T.D. Williamson delivers the tools pipelines trust to work safer, protect the environment, boost efficiency, and keep operations running without interruption. The company offers a full suite of pipeline solutions, including:

Hot tapping systems for safe, live pipeline access.

Plugging and isolation tools, including TDW SHiiELD DiiB systems.

Pipeline monitoring technologies, inline inspection and data analysis.

Pigs for cleaning, inspection, and flow maintenance.

Maintenance and repair solutions designed for efficiency and reliability.

Pressure control and bypass equipment for safe workflow management.

TDW continues to advance energized sealing, electromechanical activation, and real-time monitoring, demonstrating how experience, skill, and innovation create safer and more efficient pipeline operations.

Unlock safer, faster pipeline isolation with TDW SHiiELD

SHiiELD enables safer, faster, and emission-free isolation. Crews using existing TDW systems can integrate the technology without extensive equipment changes, leveraging next-generation isolation today.

Contact T.D. Williamson to see how SHiiELD double independent isolation and bleed technology elevates operational performance and redefine pipeline maintenance.