2

Case Study

Safe & Precise Pipeline Isolation in a High-Density Urban Environment

TDW Offering: Intervention & Isolation – STOPPLE® Train Technology

Technology: STOPPLE® Train Technology

Project Location: Singapore

Precise Pipeline Isolation in Urban Environments

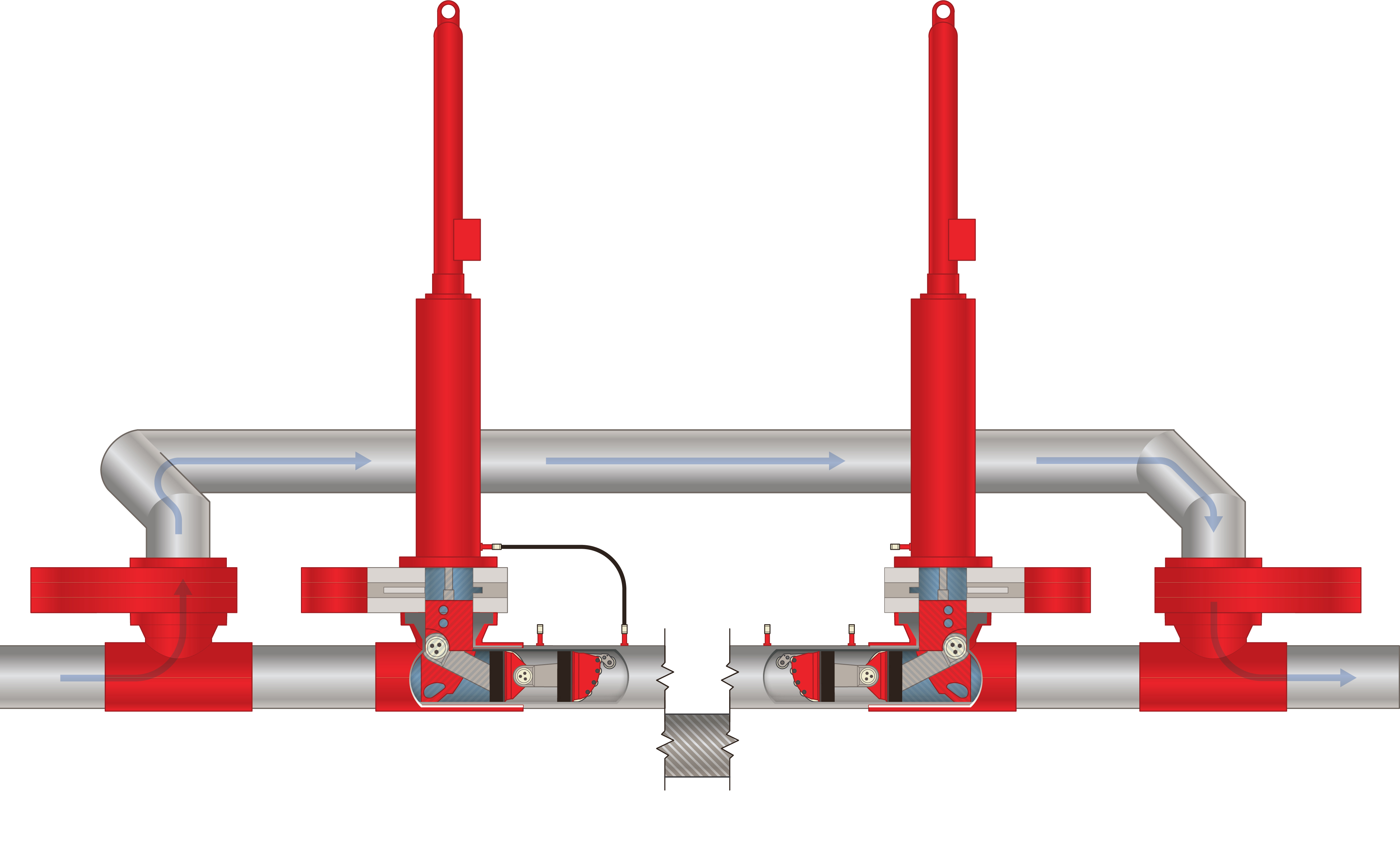

Urban pipeline operators must navigate complex infrastructure challenges while ensuring uninterrupted service and public safety. In high-density environments, precise intervention and isolation techniques are essential to maintaining operational integrity. The STOPPLE® Train isolation begins with the installation of LOCK-O-RING® Plus fittings, followed by a controlled hot tap to create an access point. Double isolation is then deployed, incorporating dedicated bypasses to sustain continuous flow. This method enables operators to execute critical pipeline modifications while minimizing risk and ensuring seamless energy supply.

Example of a typical Double STOPPLE® Train Isolation with bypass.

Pipeline Operator's Challenge

Singapore’s rapid urban expansion includes an extensive public transportation system network expansion, with underground infrastructure projects requiring careful coordination with existing utilities. As part of one such development, a pipeline operator needed to divert two high-pressure 24-inch natural gas transmission pipelines supplying gas to the market. These pipelines, operating at 40 bar (600 psi), ran directly beneath the planned subway station and were located in a highly congested area, next to a major road intersection with heavy vehicle and pedestrian traffic, flanked by an elevated highway bridge and a busy road checkpoint.

The operator faced multiple challenges:

- Ensuring uninterrupted gas supply throughout the diversion

- Executing six simultaneous isolations in confined excavation spaces

- Managing safety risks in a high-density environment with minimal clearance

- Meeting strict construction deadlines without compromising operational integrity

Given the limited space for excavation and the need for additional safety precautions to isolate each section of the two pipelines, the operator turned to TDW for expertise to engineer and execute a reliable, high-precision solution.

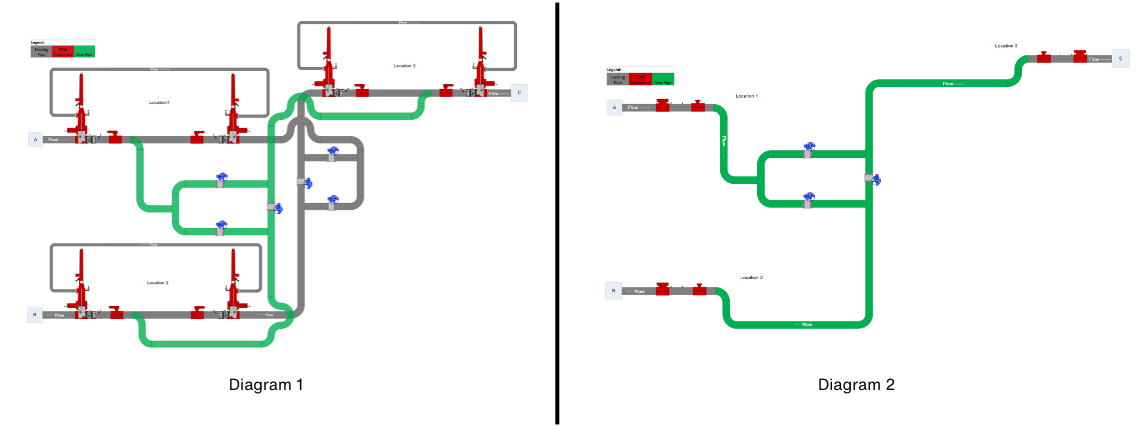

Diagram 1: jobsite with tools on the line and proposed new line in green. Diagram 2: new line after completed project.

TDW Solution

STOPPLE® Train Isolation with Bypass

TDW deployed its proven STOPPLE® Train technology with six 24-inch LOCK-O-RING® Plus fittings, allowing the operator to safely isolate the affected pipeline sections while maintaining gas flow through dedicated 24-inch bypasses.

What made this project stand out?

- Simultaneous Execution of Multiple Isolations: TDW successfully executed three double STOPPLE® Train isolations with bypasses at the same time, ensuring the pipelines remained in operation without service disruption.

- Global Equipment & Expertise Mobilization: Leveraging its global footprint, TDW coordinated the deployment of specialized equipment and personnel from multiple locations worldwide, ensuring all resources arrived on-site exactly when needed.

- Operational Execution in a Confined Urban Environment: Given the tight space constraints and proximity to key infrastructure, TDW teams applied enhanced monitoring and bleeding procedures to ensure maximum safety throughout the operation.

- 24-Hour Operations to Meet Project Timelines: TDW’s field teams worked around the clock to maintain the project schedule, demonstrating adaptability and collaboration with the operator.

Technicians hot tapping and isolating one of the 24-inch pipelines.

Outcome

Seamless Pipeline Diversion, Zero Downtime

Through meticulous planning, global collaboration, and technical expertise, TDW enabled the successful diversion of critical transmission pipelines without disrupting gas supply to the market. The operation was executed on time, safely, and in full compliance with operational and regulatory requirements.

This project underscores the role of TDW as a trusted partner for complex pipeline interventions—helping operators maintain uptime, mitigate risks, and support major infrastructure development worldwide.

Acting as One TDW

TDW extends its appreciation to our customer for their trust, professionalism, and collaboration, as well as to the TDW teams across the world who worked together to bring this project to life. This success exemplifies our shared commitment to safety, precision, and seamless teamwork.

An isolated section of pipeline with a bypass.

Emissions Eliminated

An additional benefit of isolation technology is the safe containment and capturing of any fugitive emissions which would be released to the atmosphere if blown down from a distance valve. On this jobsite, the 4,694 MSCF (132,919.28 m3) of natural gas captured equates to 2,938 tons (2,665 metric tons) of carbon dioxide equivalency.