Pipe Population Discrepancy Analysis

Do You Have All Your Material Records?

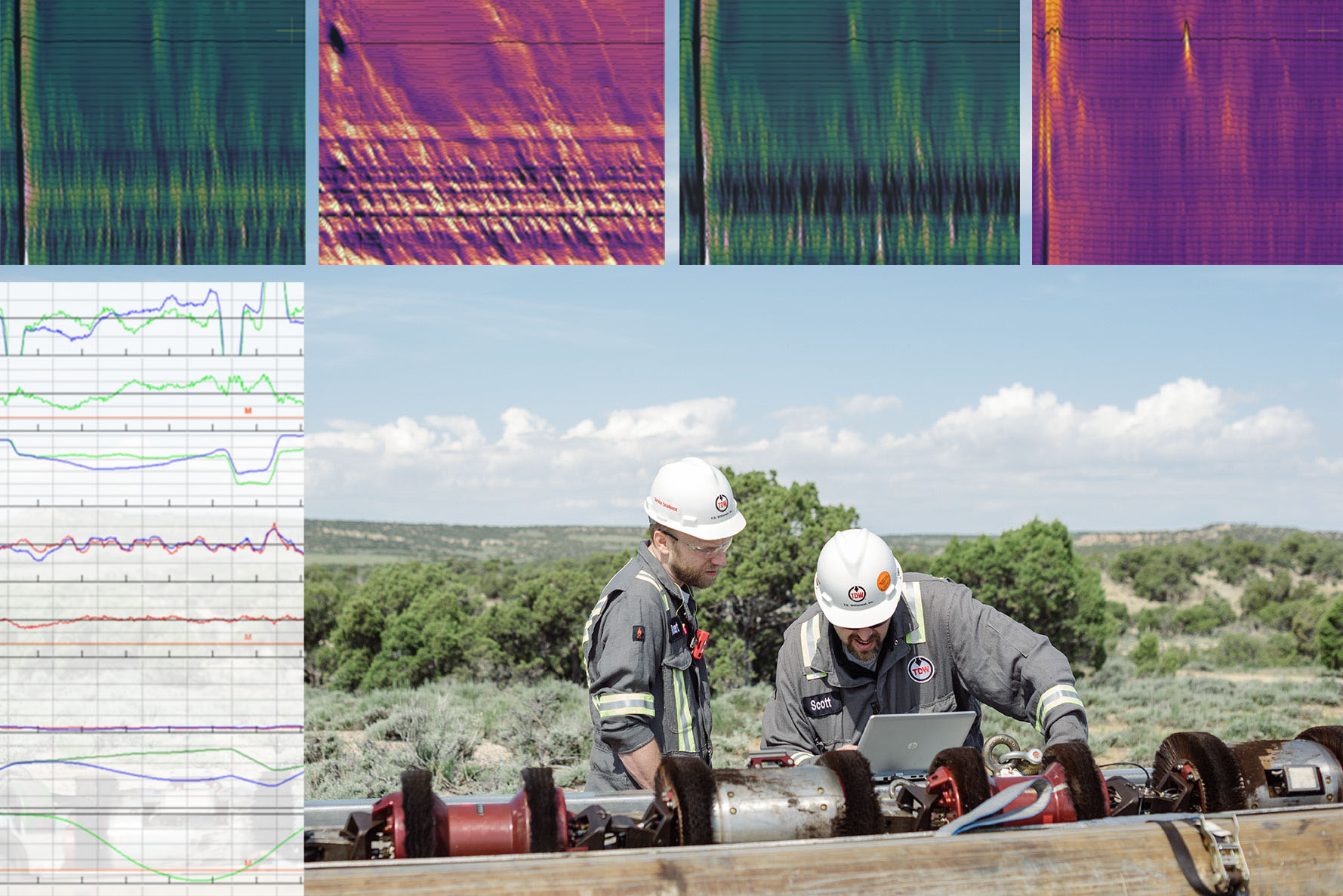

Having complete material records is important for operations, integrity and compliance. TDW integrity engineers follow a five-step process to help operators establish material records that are traceable, verifiable and complete.

Measure, Then Verify

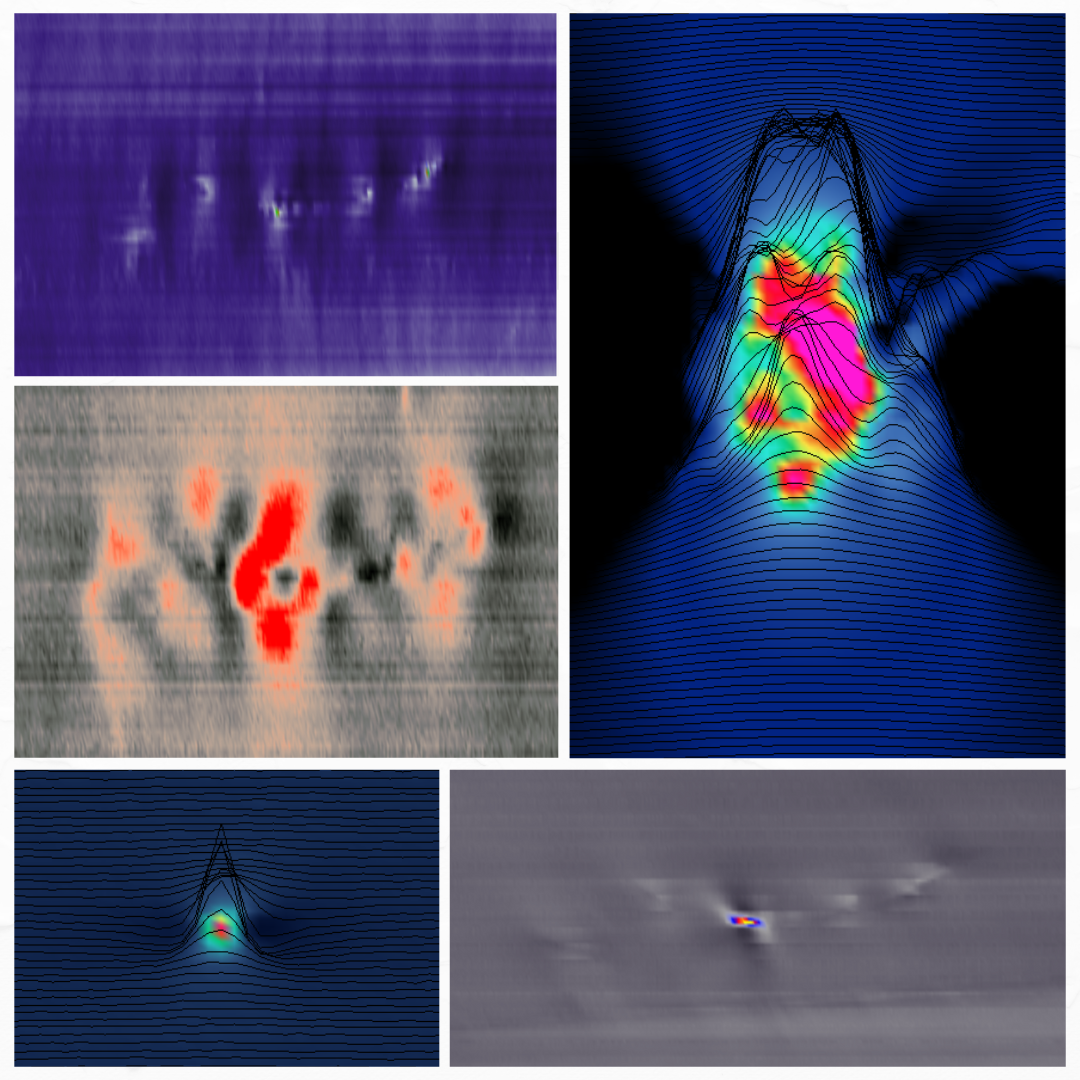

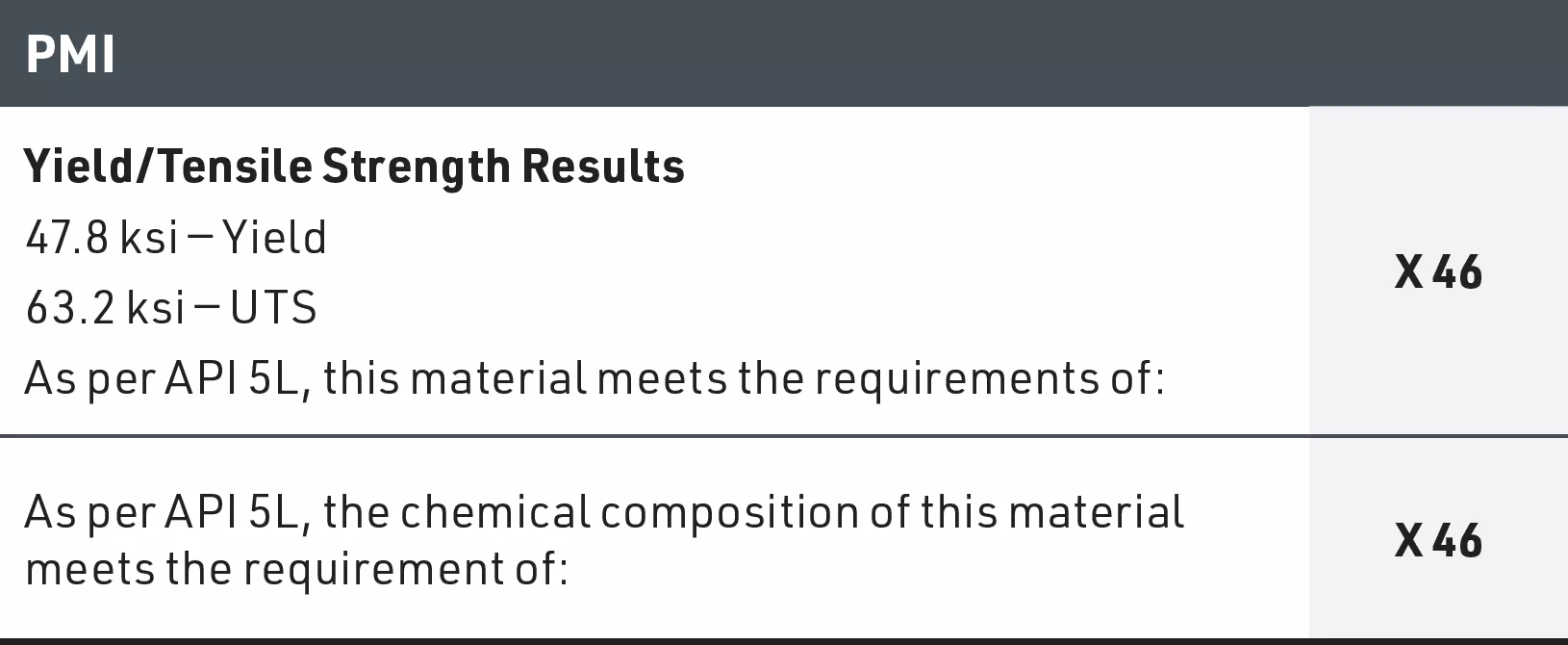

Establishing material records begins with determining what is known already and identifying gaps. Filling the gaps is achieved through a Pipe Joint Classification (PJC) process to gather in-line inspection (ILI) data followed by operator verification using various in-depth techniques.

Approach

A Five-Step Process

- STEP 1: Establish what you know first.

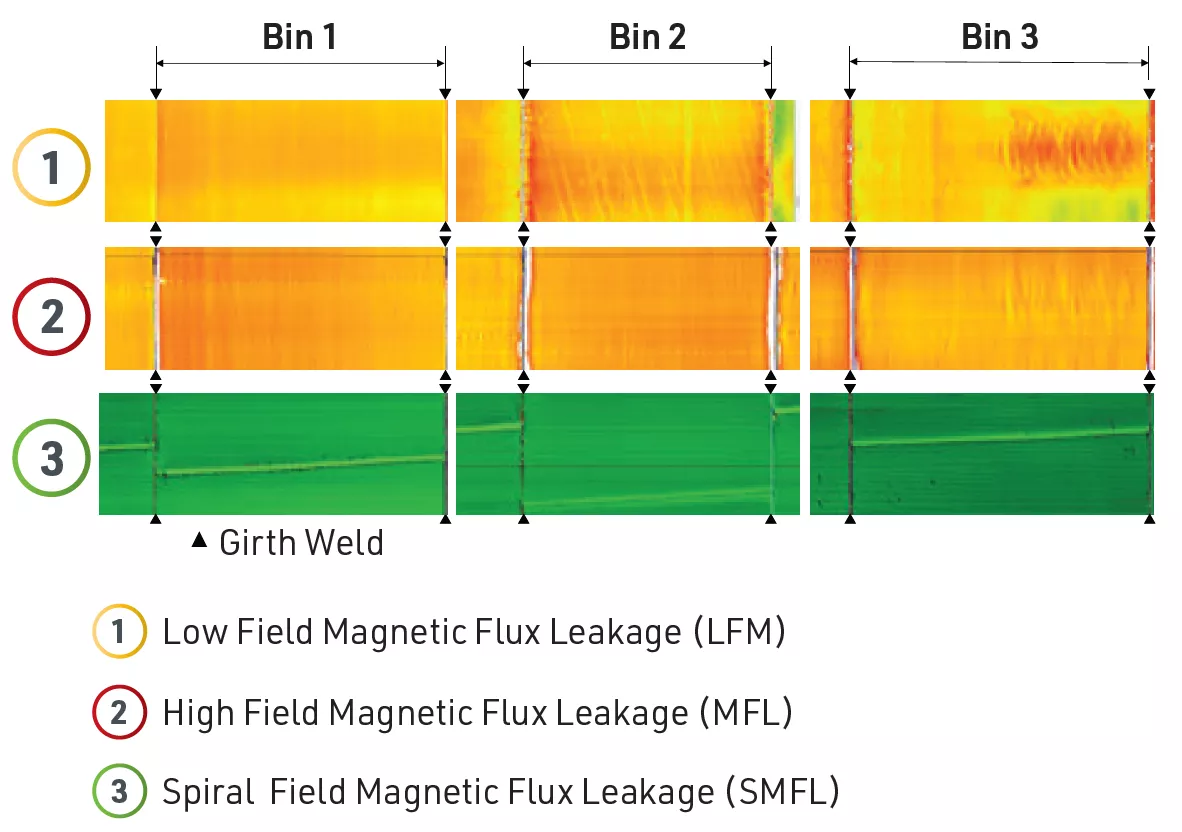

- STEP 2: Run the MDS tool and establish populations of like pipe.

- STEP 3: Perform a pipe population discrepancy analysis to identify missing information.

- STEP 4: Develop a plan to statistically sample the populations to verify and establish the missing properties.

- STEP 5: Gather the in-field nondestructive examination (NDE) samples to verify materials for each population and fill in gaps.

Value

Traceable, Verifiable and Complete

The outcome is a record of pipeline material data that is used for regulatory compliance. This will confirm metal grades are what you expected and ensure your pipeline is ready before a change in pressure or changing services, such as introducing hydrogen.