Deformation (DEF)

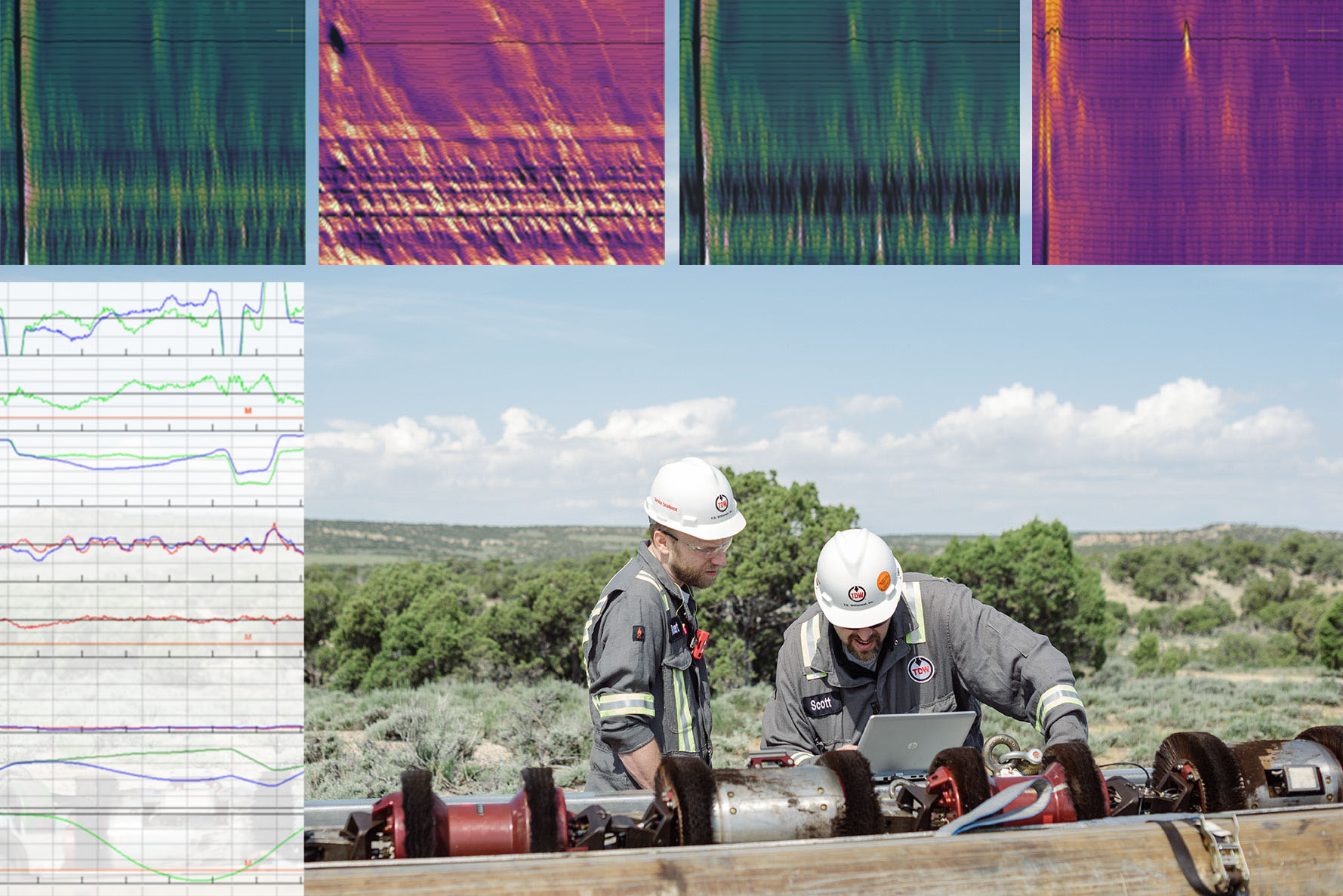

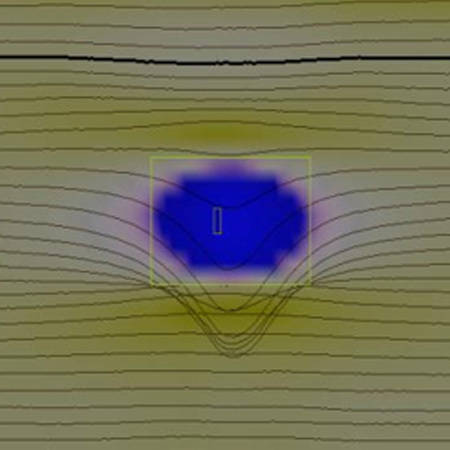

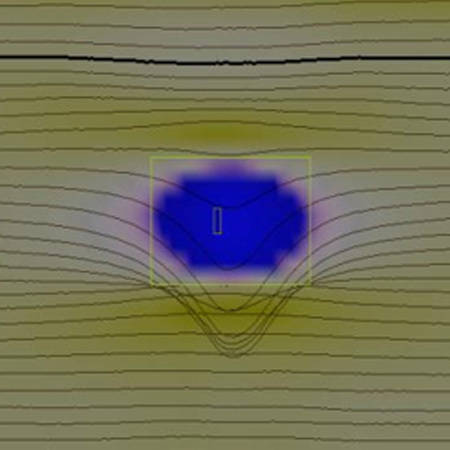

The high resolution deformation (DEF) tool provides pipeline operators with an easy and efficient way to detect minute bore reductions down to the slightest change in the pipeline’s internal diameter. The data produced is also useful for dent strain calculations, which help determine anomaly severity beyond simple dent depth. In combination with other technologies in a complete Multiple Dataset Platform, the DEF tool also plays an important role in detecting mechanical damage.

Key Features

- Sensors ride directly on the internal pipe surface, rather than behind a cup, for increased sensitivity

- Single-body tool reduces drag and weight for low pressure and flow applications

- High circumferential sensor channel count enables improved detection accuracy

- Probability of detection is 90% for Dents and Ovalities of 1% of nominal pipe OD

- Dent depth accuracy is +/-0.5% of nominal pipe OD

- Expansion accuracy is +/- 0.15% of nominal pipe OD

Sizes

- 4-inch through 48-inch

The high resolution deformation (DEF) tool provides pipeline operators with an easy and efficient way to detect minute bore reductions down to the slightest change in the pipeline’s internal diameter. The data produced is also useful for dent strain calculations, which help determine anomaly severity beyond simple dent depth. In combination with other technologies in a complete Multiple Dataset Platform, the DEF tool also plays an important role in detecting mechanical damage.

Key Features

- Sensors ride directly on the internal pipe surface, rather than behind a cup, for increased sensitivity

- Single-body tool reduces drag and weight for low pressure and flow applications

- High circumferential sensor channel count enables improved detection accuracy

- Probability of detection is 90% for Dents and Ovalities of 1% of nominal pipe OD

- Dent depth accuracy is +/-0.5% of nominal pipe OD

- Expansion accuracy is +/- 0.15% of nominal pipe OD

Sizes

- 4-inch through 48-inch