Case Study

Dent and Gouge Assessment With MDS™ Platform

TDW Offering: Pipeline Integrity

Assessment Type: Dent and Gouge Assessment

Technology: MDS™ Platform

Project Location: North America

Dealing with Dents and Gouges

By performing an in-line inspection (ILI) with the MDS™ platform and proprietary assessment methodology, we can detect, identify and size dent and gouge combinations, thereby discriminating between higher-risk and less onerous defects. The result is a severity ranking that enables an optimized repair process.

Pipeline Operator's Challenge

A customer recently deployed our MDS™ platform to complete a routine in-line inspection on a pipe segment containing a high-consequence area near a residential neighborhood and a waterway.

TDW Solution

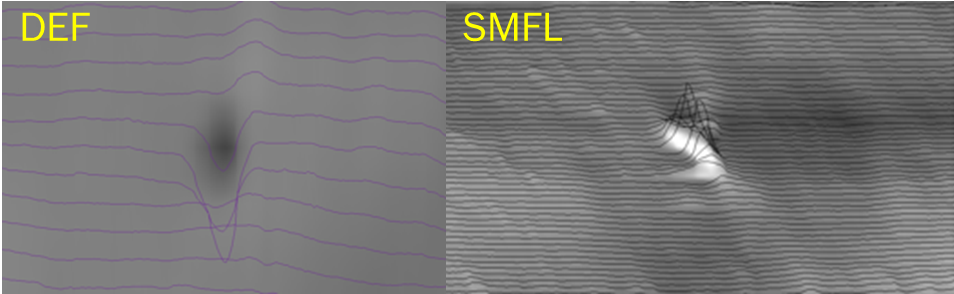

The MDS Tool utilized multiple ILI technologies to detect and classify an axially oriented dent with interacting metal loss that posed an increased risk to pipeline integrity.

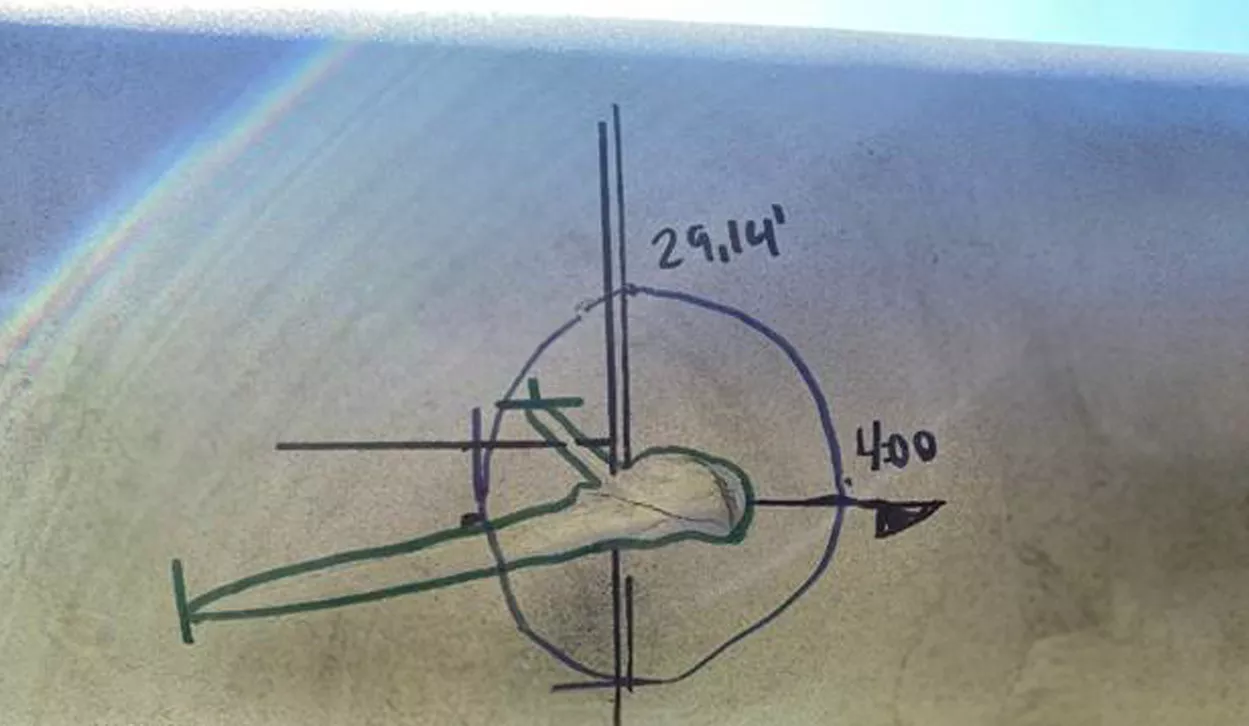

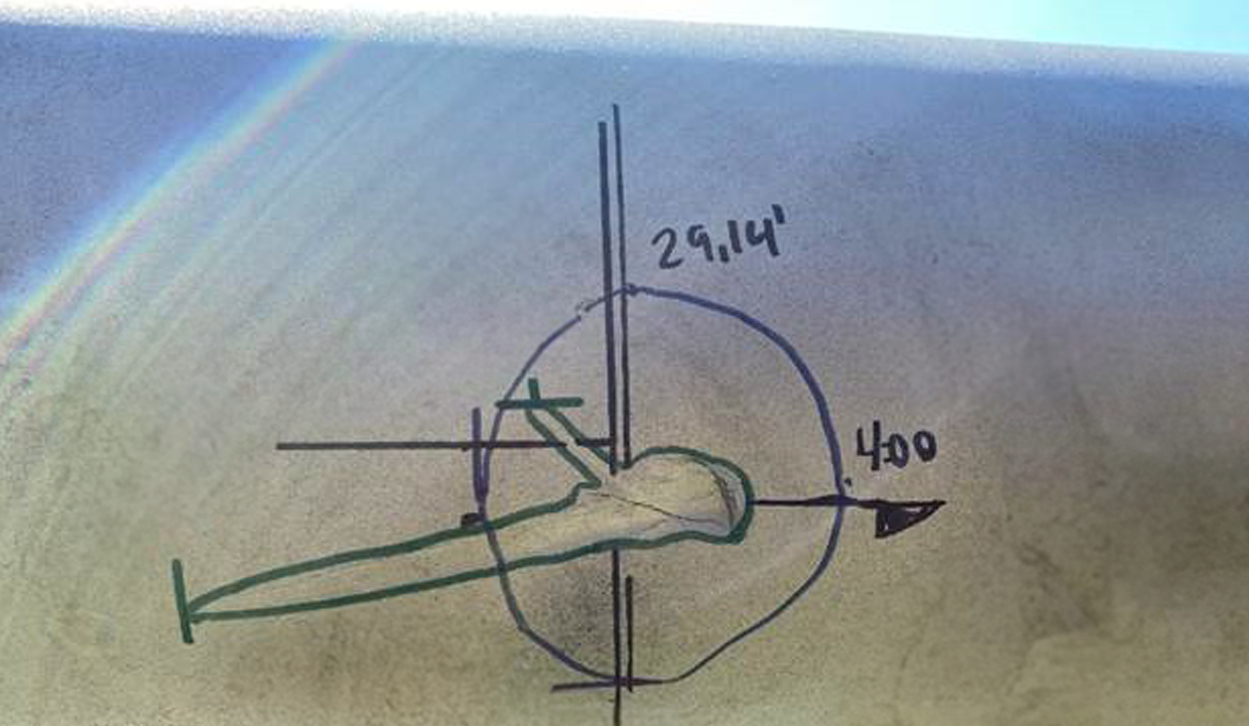

Clear indication of a dent (GEO data) with metal loss. Spiral MFL (SMFL) data indicates the feature is axially oriented.

Outcome

The operator was able to identify the elevated threat of this dent with a gouge anomaly from the report. This allowed them to prioritize this dig, mitigating the risk to the environment.

Customer Quote: “I’m thankful that you guys identified and reported this to us. Definitely a win for the MDS tool and your analysis team!”

Actual gouge feature found by the operator in the field.