Case Study

Assessment of Eastern European Pipeline with Microbial Attack

TDW Offering: Integrity Engineering Solutions

Assessment Type: Corrosion Growth

Technology: Deformation (DEF) + Magnetic Flux Leakage (MFL)

Project Location: Eastern Europe

Dealing with Corrosion

Corrosion continues to be one of the primary threats to pipelines. The most common way to assess corrosion is through in-line inspection (ILI). While the most recent ILI report is a statement of the current integrity, additional assessments are required to predict the future. One inspection can be a basis, but multiple inspections let you see what’s happening between them, providing an insight into what the future might hold.

Pipeline Operator's Challenge

A customer had a significant amount of deep internal corrosion because of microbial attack coming from the well system. The corrosion was severe enough that the operator wasn't sure whether it would require a new pipeline, or if it could be repaired.

Customer launch facility in year one (left) and year three (right).

TDW Solution

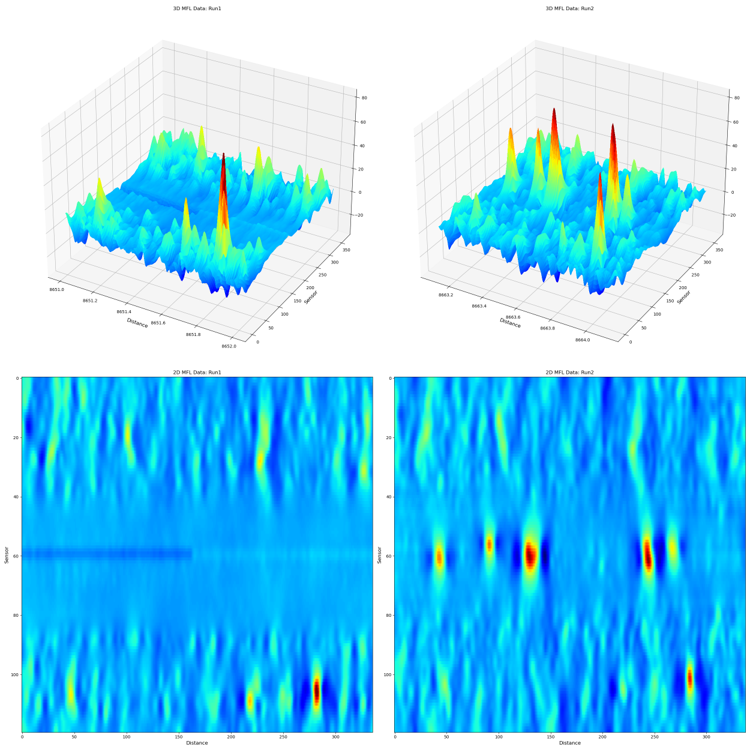

Using the data from two MFL runs, a corrosion growth assessment was conducted and the growth rate was confirmed as detrimental to future pipeline operations.

|

First run, year one ILI data (left) and second run, year three ILI data (right).

Outcome

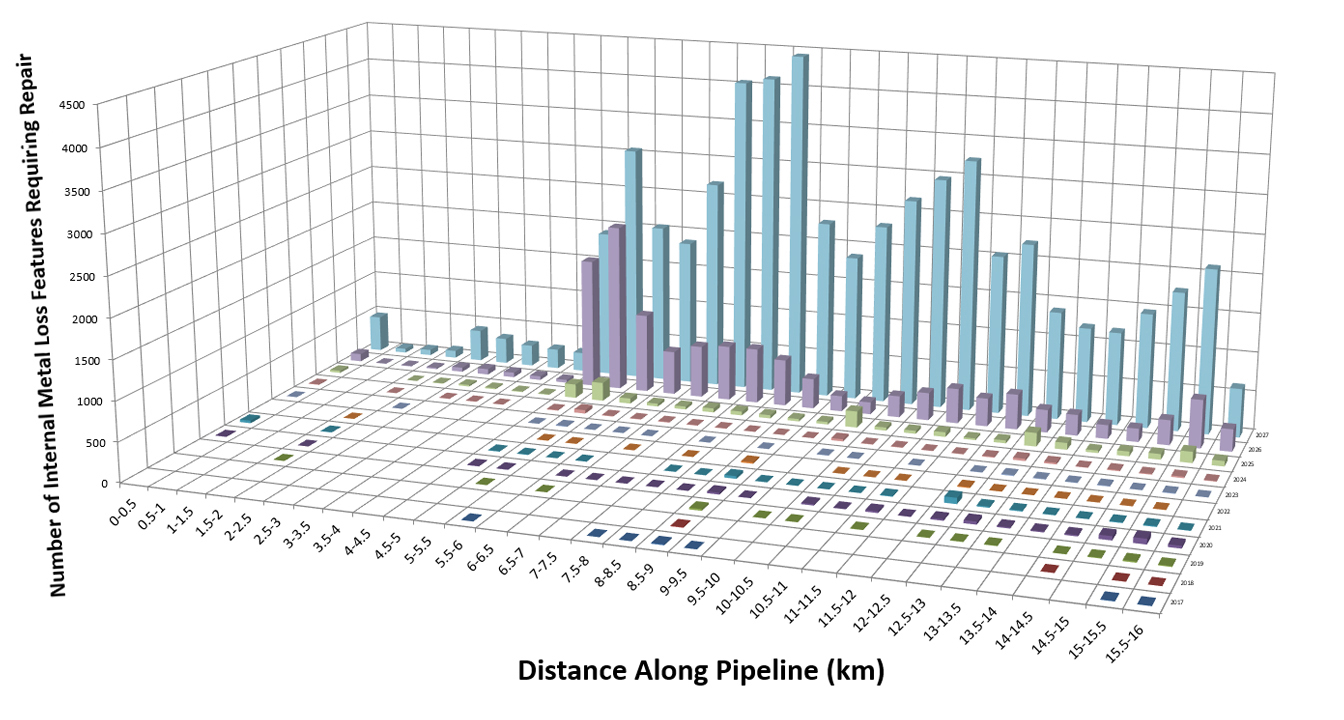

The results of this analysis clearly indicated the extent of the damage that had occurred across the pipeline. Armed with this information, the operator confidently knew which sections of the system could be repaired, and which section should be outright replaced.

Repair plan showing the number of internal metal loss features requiring repair mapped over distance along the pipeline