Why TDW Field Services?

Why TDW Field Services?

Your pipeline reliability is in their hands.

How We're DifferentAt a Glance

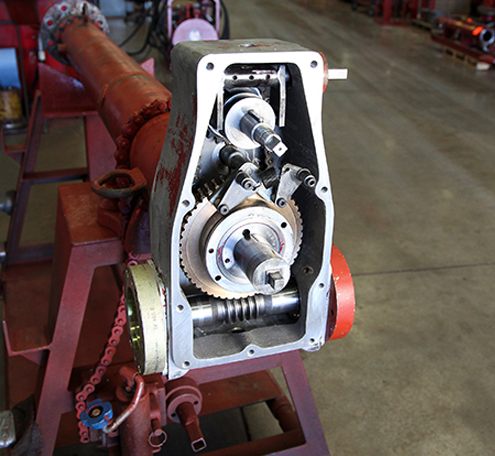

Aftermarket Services

Maintained and Ready

Minimize downtime, increase productivity and maximize your investments.

Sustainability

Championing a More Sustainable Future

Our isolation, pigging and integrity solutions help reduce or eliminate emissions...

Quick-Ship Pigs & Components

Stocked and Ready to Go

Get the pigs and components you need, exactly when you need them.