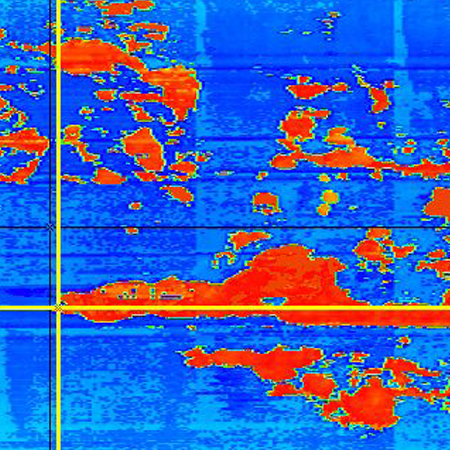

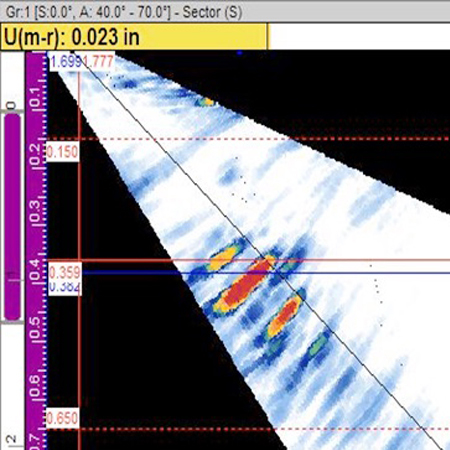

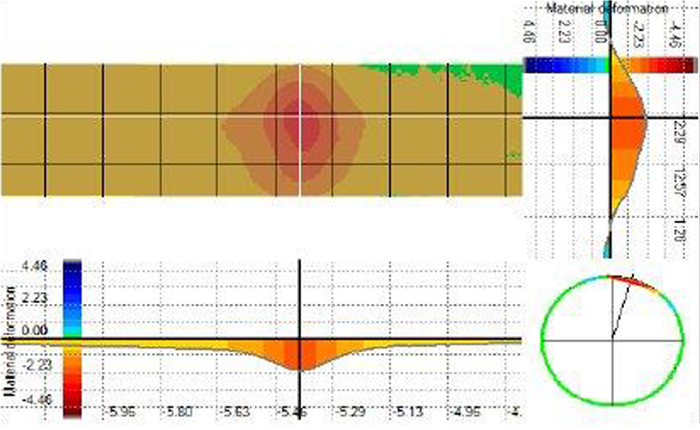

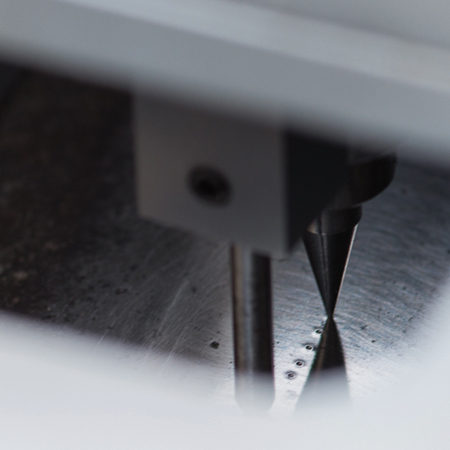

Performed by American Society for Nondestructive Testing (ASNT)-certified Level II and Level III technicians, our non-destructive evaluation (NDE) methods verify and drive the accuracy of in-line inspection (ILI) results while pipelines remain in service.

non-destructive-evaluation-nde Products

Non-Destructive Evaluation