Phased Array

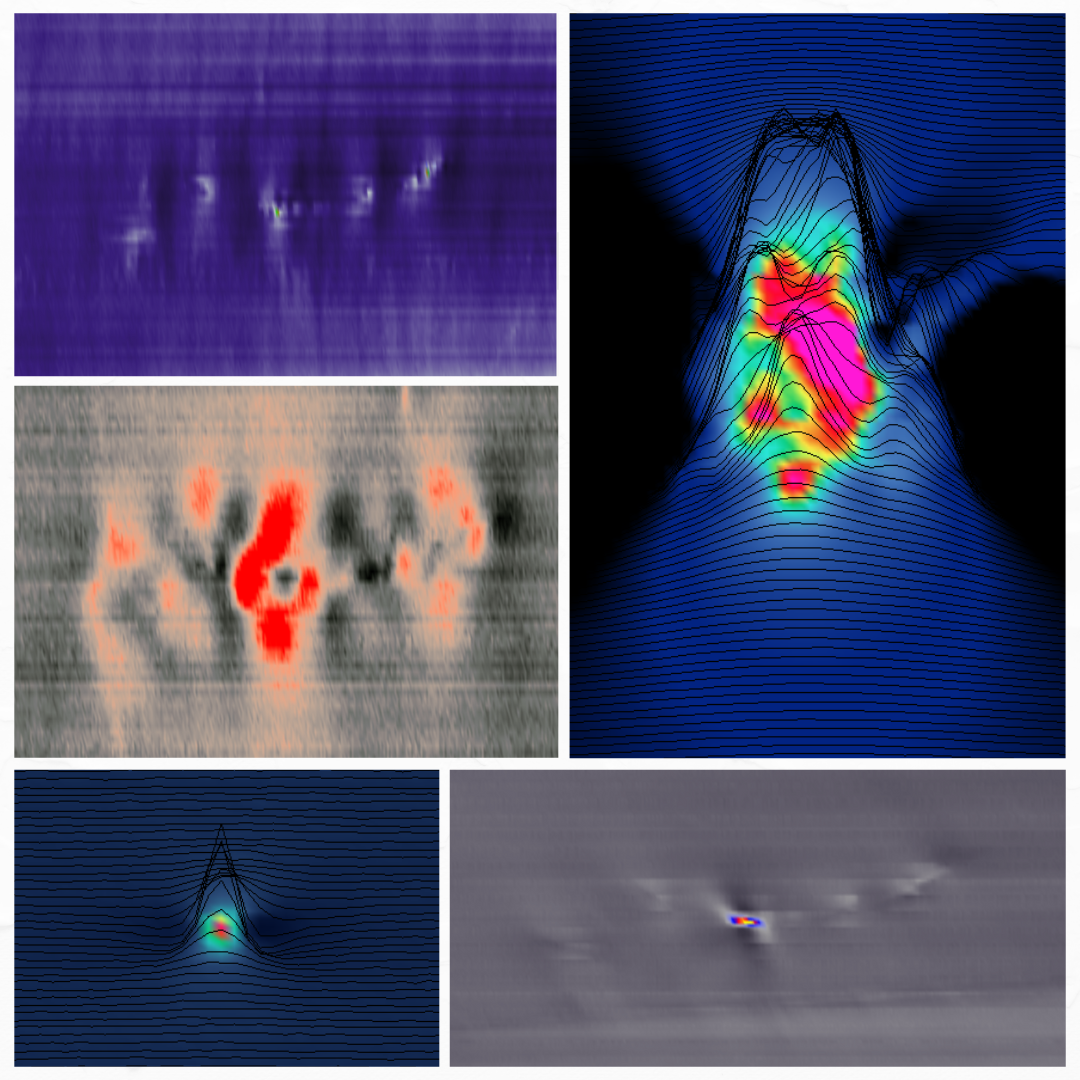

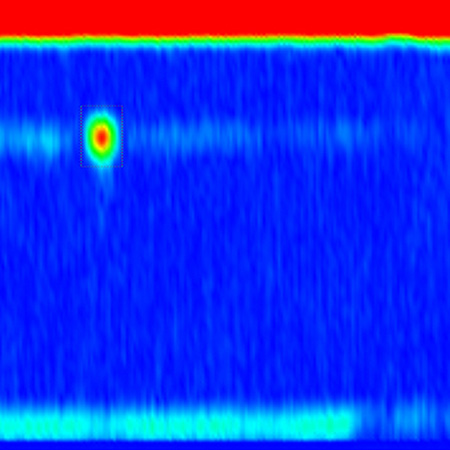

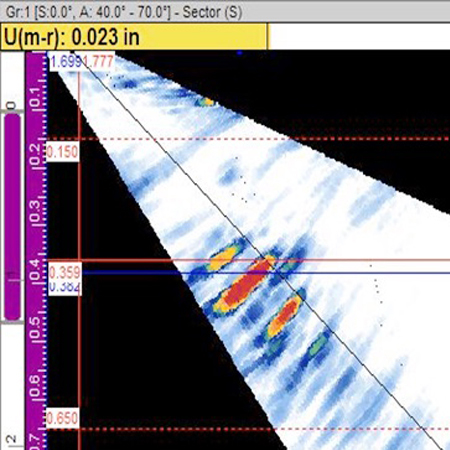

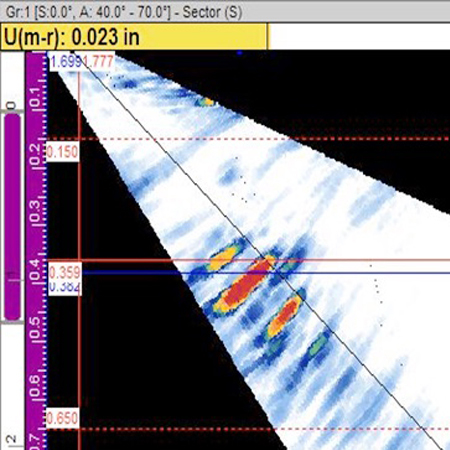

Considered the gold standard of ultrasonic (UT) inspection, phased array is an advanced non-destructive evaluation method that enhances the sensitivity and efficiency of ultrasonic inspections.

Phased array allows for permanent documentation and screen shots of acquired data, enabling planar anomaly monitoring and growth analysis. Designed to cover more surface area with fewer tool passes, phased array UT saves time and money compared to other technologies. A properly designed phase array inspection plan can perform several different inspections without changing hardware, saving inspection time and expenses.

Key Features

- Captures data simultaneously from a range of elements for greater precision

- Performs 0° inspections with heightened sensitivity compared to manual ultrasonic-0°

- Displays images in real time, showing the depth and location of flaws relative to the probe

- Data storage capabilities allow for replay and retention of a complete inspection record

- Requires significantly less inspection space for scanning compared to automated ultrasound technology

- TDW field technicians are certified to SNT-TC-1A and API QUPA Individual Certification Programs

Considered the gold standard of ultrasonic (UT) inspection, phased array is an advanced non-destructive evaluation method that enhances the sensitivity and efficiency of ultrasonic inspections.

Phased array allows for permanent documentation and screen shots of acquired data, enabling planar anomaly monitoring and growth analysis. Designed to cover more surface area with fewer tool passes, phased array UT saves time and money compared to other technologies. A properly designed phase array inspection plan can perform several different inspections without changing hardware, saving inspection time and expenses.

Key Features

- Captures data simultaneously from a range of elements for greater precision

- Performs 0° inspections with heightened sensitivity compared to manual ultrasonic-0°

- Displays images in real time, showing the depth and location of flaws relative to the probe

- Data storage capabilities allow for replay and retention of a complete inspection record

- Requires significantly less inspection space for scanning compared to automated ultrasound technology

- TDW field technicians are certified to SNT-TC-1A and API QUPA Individual Certification Programs