Magnetic Flux Leakage (MFL)

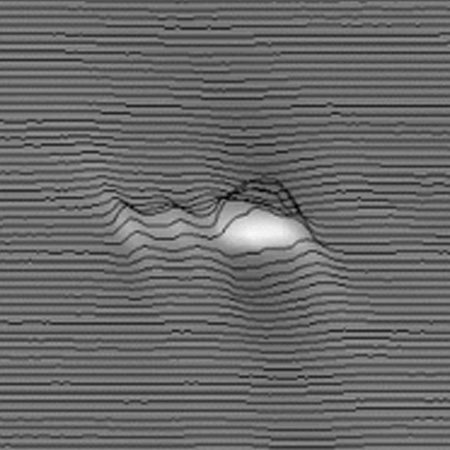

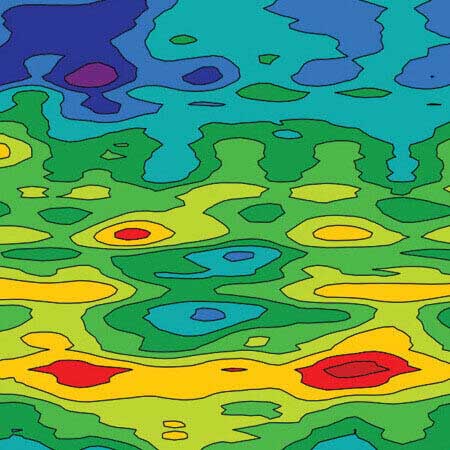

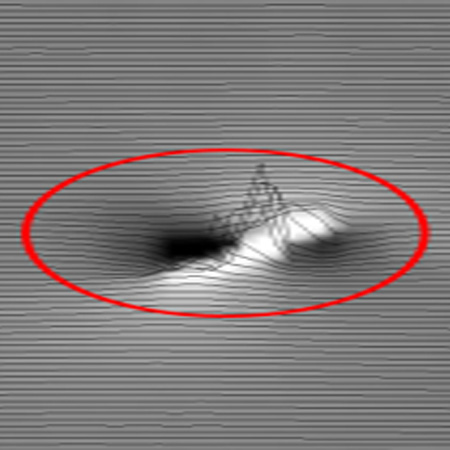

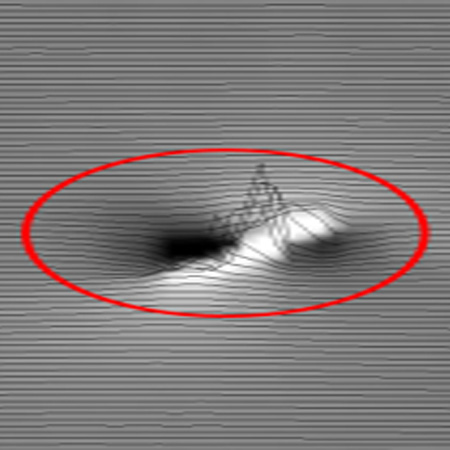

High resolution magnetic flux leakage (MFL) technology provides accurate detection and sizing of metal loss and internal versus external discrimination to help operators remain in regulatory compliance and extend their pipeline system's useful life.

Key Features

- Can be combined with other technologies to minimize the number of inspection tool runs

- 4-inch, 6-inch and 8-inch tools are improved to be shorter, lighter and produce less drag than previous tool designs

Sizes

4-inch through 22-inch

High resolution magnetic flux leakage (MFL) technology provides accurate detection and sizing of metal loss and internal versus external discrimination to help operators remain in regulatory compliance and extend their pipeline system's useful life.

Key Features

- Can be combined with other technologies to minimize the number of inspection tool runs

- 4-inch, 6-inch and 8-inch tools are improved to be shorter, lighter and produce less drag than previous tool designs

Sizes

4-inch through 22-inch