Equipment Type

Pressure/ANSI Class

Size

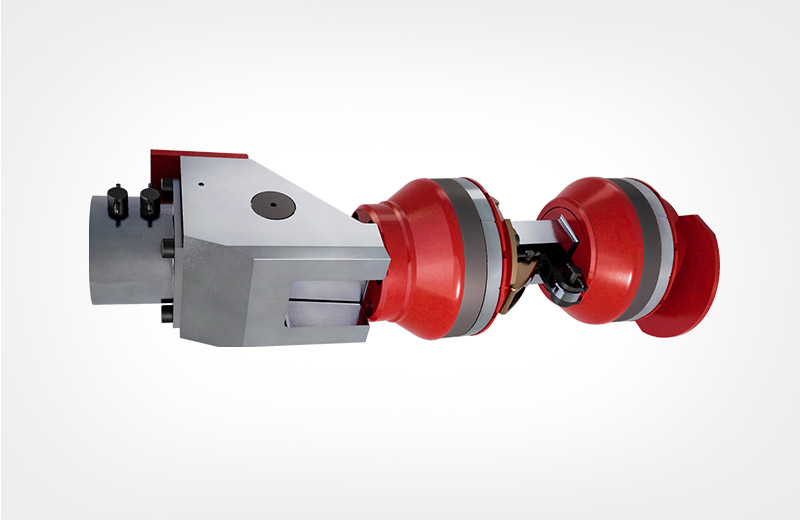

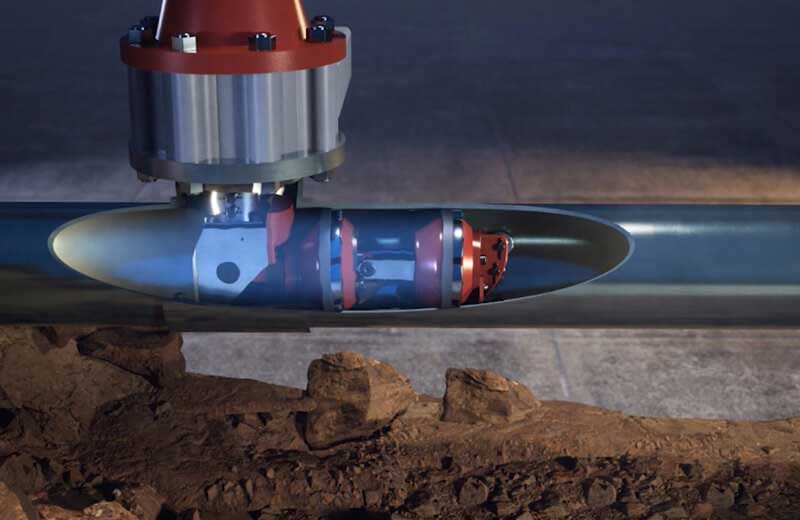

The easy-to-use ProStopp® DS isolation tool is a low-pressure double block and bleed technology specifically designed for the gas distribution industry. The double block and bleed feature allows for total leak protection so repairs and maintenance can be safely performed on in-service pipelines. The area between the two plugging heads is depressurized through the housing which means no additional taps or fittings are required. The tool utilizes an energized seal which expands inside the pipe. This seal can accommodate multiple wall thicknesses which reduces inventory needs for the operator.

Specifications

- For schedule 10-60 pressurized carbon steel pipe.

- 6-inch through 12-inch.

- Maximum working pressure: 20 bar (300 psi).

Key Features

- Smaller than the internal diameter of the pipe, resulting in faster, more reliable operations.

- Chip sweep built into the plugging head shifts excess cutter shavings out of the way of the seal.

- Compatible with TDW fittings and valves, reducing inventory costs.

- Reusable sealing element.

- Tool is operated from the ground, eliminating the risk associated with technicians working from various heights.

Common Applications

- Performing double block and bleed isolations on low-pressure gas distribution pipelines

The easy-to-use ProStopp® DS isolation tool is a low-pressure double block and bleed technology specifically designed for the gas distribution industry. The double block and bleed feature allows for total leak protection so repairs and maintenance can be safely performed on in-service pipelines. The area between the two plugging heads is depressurized through the housing which means no additional taps or fittings are required. The tool utilizes an energized seal which expands inside the pipe. This seal can accommodate multiple wall thicknesses which reduces inventory needs for the operator.

Equipment Type

Pressure/ANSI Class

Size

Specifications

- For schedule 10-60 pressurized carbon steel pipe.

- 6-inch through 12-inch.

- Maximum working pressure: 20 bar (300 psi).

Key Features

- Smaller than the internal diameter of the pipe, resulting in faster, more reliable operations.

- Chip sweep built into the plugging head shifts excess cutter shavings out of the way of the seal.

- Compatible with TDW fittings and valves, reducing inventory costs.

- Reusable sealing element.

- Tool is operated from the ground, eliminating the risk associated with technicians working from various heights.

Common Applications

- Performing double block and bleed isolations on low-pressure gas distribution pipelines