Improved Operation and Throughput

Pipeline pigging is a vital component of pipeline maintenance, operation and integrity, helping ensure the health of your pipeline system.

Pigging solutions can improve pipeline flow, increase operating efficiency and safety, reduce costs and minimize downtime. A well-planned pigging program helps lower the risk of leaks and fugitive emissions. It also prepares pipelines for safely transporting emerging fuels, including hydrogen, that may be associated with new or increased risks.

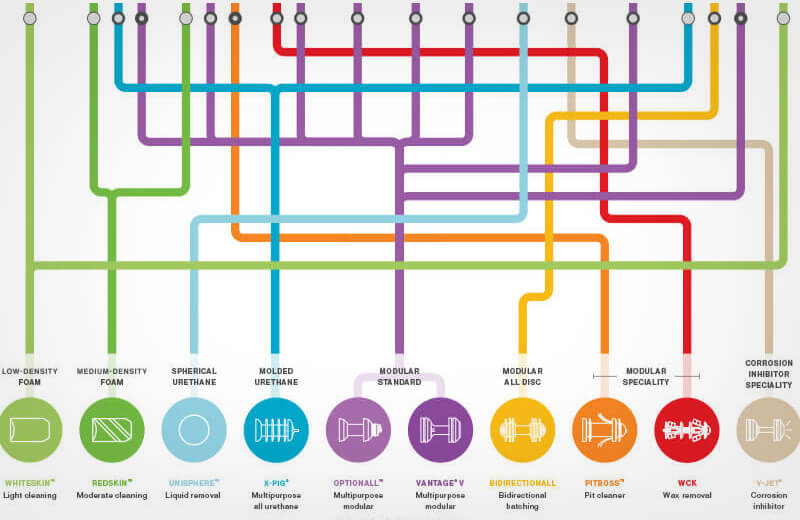

TDW is a pioneer among the world’s pigging companies and pig manufacturers, with a wide range of best-in-class solutions. These include purpose-built pigs for successful, assurance-based cleaning programs, quick-actuating closures that help ensure operator and environmental safety and industry-leading pig passage indicators designed for accurate pig detection.

No two pipelines are alike. TDW engineers have the expertise to recommend the right equipment and pigging program for your pipeline, your product and your goals.